How to protect welds from corrosion?

Corrosion is one of the most common threats that can destroy the quality and durability of welds. In the industrial sector, protecting welds against corrosion is essential. Today, we will present detailed information on effective methods of weld protection and answer the question, how to protect welds against corrosion wherever reliability and structural longevity are crucial.

In today’s article, you will find:

- What is corrosion and why is it dangerous for welds?

- Which methods of weld protection against corrosion are the most effective?

- Why is corrosion protection of welds crucial in industry?

- Which welding machines and accessories can help protect welds?

- Weld protection against corrosion in practice – step by step

What is corrosion and why is it dangerous for welds?

Corrosion is a chemical process in which metal reacts with the environment, leading to gradual degradation. In the case of welds, corrosion can weaken the structure, resulting in reduced strength and durability. This is especially important in constructions that must withstand heavy loads or harsh weather conditions.

Welds, as the joining points of elements, are often more susceptible to corrosion than other parts of the structure, particularly where microcracks may appear, accumulating moisture and contaminants. That is why effective weld protection against corrosion is so important.

Which methods of weld protection against corrosion are the most effective?

1. Protective coatings for welds

One of the most common methods is the application of anti-corrosion coatings. This can be done in several ways:

- Painting: Applying anti-corrosion paints is one of the simplest methods. High-quality paint forms a protective barrier that prevents water and aggressive chemicals from reaching the weld.

- Lacquering: Protective lacquers, especially those based on epoxy resins, can effectively shield welds by forming a durable and flexible coating.

2. Galvanizing welds

Galvanizing involves applying a layer of zinc to the metal. This is one of the most effective corrosion protection methods, especially for steel. The zinc layer provides electrochemical protection, preventing metal oxidation.

3. Galvanic coatings

Welds can also be protected using galvanic coatings such as chromium or nickel plating. These coatings are thin but highly effective in preventing metal contact with moisture and oxygen, significantly extending weld life.

4. Specialized protective products

There are various chemical products available for weld protection. What to use if not mechanical coatings? The answer lies in products that penetrate the metal surface, forming a protective layer that not only prevents corrosion but also supports weld regeneration. Look for pastes or anti-corrosion greases designed specifically for welds.

5. Passivation for corrosion protection

Passivation is a process that forms a protective layer on the metal surface to guard against corrosion. It is particularly popular for stainless steel, which gains resistance to external factors through passivation.

Why is corrosion protection of welds crucial in industry?

In industry, especially in the construction, automotive, and energy sectors, welds connect critical parts of machines and structures. If corrosion is not properly addressed, it may weaken the structure or, in the worst case, cause failure. Therefore, corrosion protection is not only necessary but also a safety investment.

Which welding machines and accessories can help protect welds?

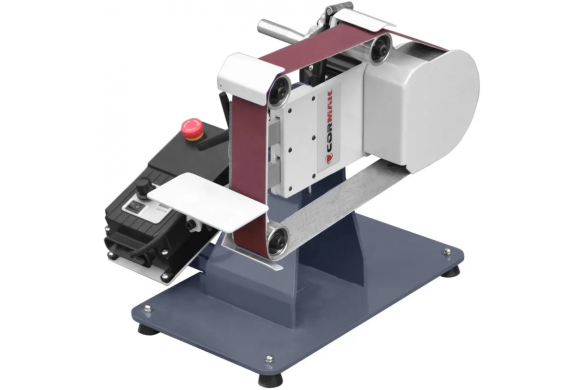

Corrosion protection doesn't end with the protective process itself. It's worth investing in proper metalworking machines and laser welders, which enable precise joining with minimal microcracking risk.

Also consider welding accessories such as gas shields, filler materials, and weld cleaning tools. The right equipment from an industrial machinery manufacturer ensures high-quality welds, which positively affects the effectiveness of corrosion protection.

Weld protection against corrosion in practice – step by step

- Surface preparation – before any treatment, thoroughly clean the weld of all contaminants. This may involve mechanical, chemical, or thermal cleaning.

- Applying the protective agent – depending on the method, apply coatings, galvanize, or perform passivation.

- Weld quality inspection – after protection, check whether the coating has been applied correctly and is free from defects that could promote corrosion.

- Regular maintenance – weld protection doesn’t end with the first application. Regular inspections and maintenance are essential to keep protection at the right level.

Remember, proper weld protection is an investment in the structure’s longevity and user safety.