How Does a Fiber Laser Work?

Table of contents:

- What is a fiber laser?

- How does a fiber laser work?

- Applications of fiber lasers

- Advantages of fiber laser technology

- Why choose Cormak fiber lasers?

- Summary

What is a fiber laser?

A fiber laser is a modern device that uses fiber-optic technology for precise metal cutting and engraving. The laser beam is generated in a fiber source and transmitted through optical fibers without mirrors or reflective lenses.

How does a fiber laser work?

The laser works by amplifying light within a fiber medium doped with rare-earth elements (such as ytterbium). Pump diodes generate light that is transmitted into the fiber, where it is amplified and converted into a powerful, focused beam capable of melting or vaporizing metal with extreme precision.

Applications of fiber lasers

Fiber lasers are widely used in industries such as:

-

metal cutting – steel, aluminium, copper, brass, titanium;

-

engraving and marking;

-

machinery and structural parts production;

-

automotive and electronics sectors.

Advantages of fiber laser technology

-

High precision – smooth, burr-free edges without finishing.

-

Energy efficiency – lower power consumption than CO₂ lasers.

-

Low maintenance – no mirrors, no calibration needed.

-

Long lifespan – up to 100,000 operating hours.

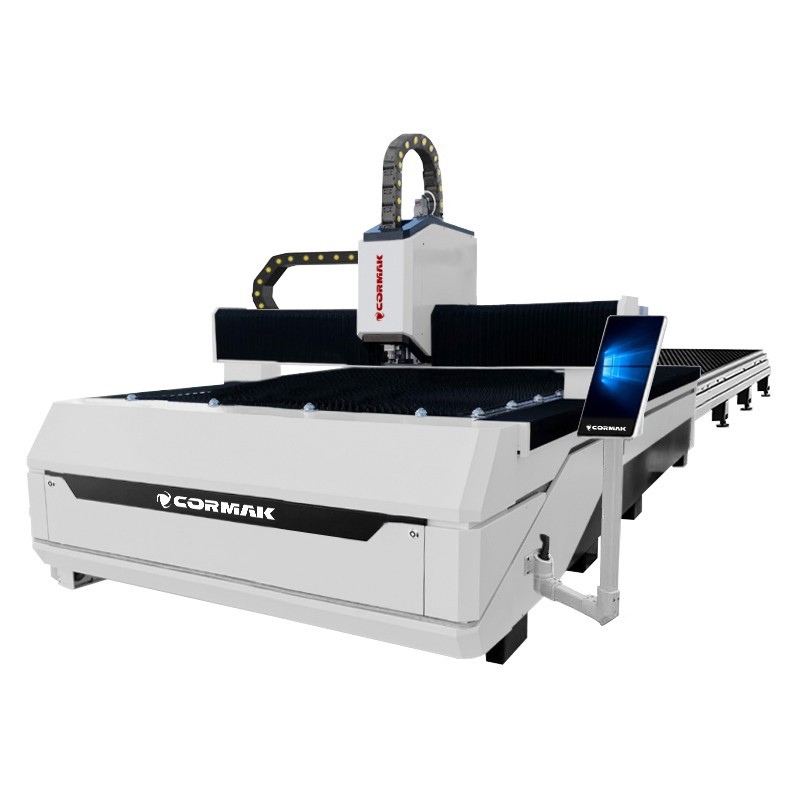

Why choose Cormak fiber lasers?

Cormak fiber lasers combine innovation and industrial reliability, offering precise cutting, stability, and high performance. Available in various power and table size options for every production need.

Summary

Fiber lasers are the future of metal cutting and marking — combining precision, durability, and cost efficiency. With Cormak, you get advanced technology designed to boost productivity and accuracy.