How and with what do you weld aluminium? What does laser welding of aluminium look like?

Laser welding of aluminum is one of the most common tasks in the metal industry, especially in vehicle manufacturing, aerospace, and electronics. Due to its unique properties, aluminum requires a special approach and appropriate tools. Today, we’ll explain how to weld aluminum, what tools to use, and which methods are most effective, including the popular laser welding technique.

In this article you will learn:

- Can aluminum be welded?

- What tools are used to weld aluminum?

- Laser welding of aluminum – a modern method

- Preparing the surface for aluminum welding

- Is welding aluminum harmful?

Can aluminum be welded?

Let’s start with the question: can aluminum be welded? Definitely yes! Thanks to its properties, aluminum is a weldable material. However, keep in mind that welding aluminum differs from welding steel or other metals. It requires greater precision, proper equipment, and the use of specialized materials. So, can aluminum be welded? Yes, but only under the right conditions to ensure the success of the process.

What tools are used to weld aluminum?

The tools used to weld aluminum depend on the chosen welding method. The most commonly used technologies are MIG/MAG, TIG, and laser welding. The choice of method depends on the material thickness, type of joint, and required strength. Selecting the appropriate wire is also crucial. What is the best wire for aluminum welding? Usually, wires made from aluminum or aluminum alloys are used, tailored to the material being welded.

Laser welding of aluminum – a modern method

Laser welding of aluminum is an advanced welding technique that uses a focused laser beam to melt the material. It is a highly precise method that guarantees high weld quality, minimal material deformation, and very little spatter. Laser welding of aluminum is especially useful for components with tight tolerances and high-quality requirements, such as in the aerospace or automotive industries.

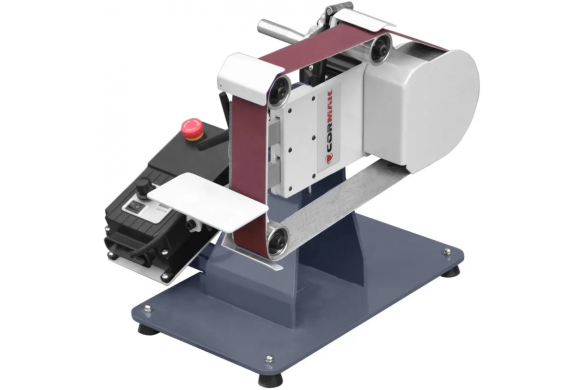

Lasers used in welding provide precise energy concentration, allowing for fast and effective metal melting with minimal impact on the surrounding material. This is why it is increasingly used in industrial machinery production. If you're interested in laser welders, check out Cormak’s offer on the industrial machinery manufacturer’s website.

What machines are used to weld aluminum?

MIG/MAG and TIG welders are the most commonly chosen machines for aluminum welding. However, if you’re aiming for precision, speed, and quality, it’s worth considering laser welders. They make the welding process faster, and the results are more durable and aesthetically pleasing. Laser welders are a modern solution for precision part manufacturing, especially in the machinery industry. Metalworking machines equipped with this technology can offer significantly better results.

Preparing the surface for aluminum welding

It’s important to properly prepare the surface before welding aluminum. This metal is especially prone to corrosion, so it is crucial to thoroughly clean the material from contaminants like oils, greases, or oxides. For this purpose, brushing, sandblasting, or other cleaning methods are used. Proper surface preparation ensures better weld quality and minimizes the risk of defects in the finished product. These steps make aluminum welding more efficient, with results that meet even the highest quality standards.

Is welding aluminum harmful?

Welding aluminum, like any other welding method, carries certain risks. But is it harmful enough to avoid? The main concerns are the emission of aluminum oxides and inhalation of fumes generated during the welding process. It’s important to properly ventilate the workspace and use protective equipment like welding masks and protective clothing.

Also, remember that welding aluminum can release harmful fumes, so using high-quality welding accessories to protect the respiratory system and ensuring proper ventilation is essential.

Summary

What tools should you use to weld aluminum? The right method depends on many factors, such as material thickness, required precision, and joint type. MIG/MAG or TIG welding is suitable for standard applications, but if you want exceptional precision, consider investing in laser welding. With the right equipment like laser welders and matching welding wire, the process becomes easier, faster, and more efficient. Also, remember safety guidelines to ensure a comfortable and safe experience when working with aluminum.

If you want to learn more about industrial welding machines, check out the full offer on the industrial machinery manufacturer's website.