gross €567.69

A set of folding knives for indexable plates. Complete with Roughing Knife and Inserts, Finishing Knife and Inserts, Grooving and Parting Knife, External Threading Knife and Boring Bar.

Thanks to the innovative solutions this lathe offers accuracy and repeatability of positioning of 0.004 mm in X/Z axes (compared to 0.01 mm for ordinary CNC lathes).

The spindle balancing accuracy equals to 0.3 g/mm and the spindle axis radial run-out is lesser than 0.002 mm (other manufacturers do not even provide these parameters).

X/Z axes positioning accuracy repeatability: 0.001 mm

Spindle root run-out: < 0.002 mm

Spindle dynamic balancing accuracy: 0.3 g/mm

Chuck repeatability: ± 0.0001 mm

Gun clamping force: 3600 kilogram-force

Spindle torque: 240 Nm

X/Z axes quick feed: 30 m/min, 36 m/min

Servo-gun index time: 0.15s

Chuck surface finish: Ra 0.2~0.4 µm (surface hardness HRC58~63)

Single-sided cutting depth: 7 mm (steel bar #45)

Drilling: Ф30 mm

Internal turning: 5 mm (on roll Ф75 mm)

Machine’s stability improves the removal of heavy material.

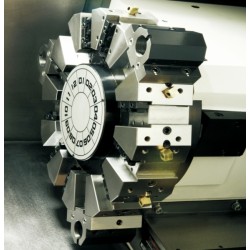

The short time of chuck index reduces the time it takes to change the tool. The highest class of bolts with ball nuts and linear guides provide quick and stable feed and delivery. High precision improves production efficiency when strict accuracy conditions matter.

The highest precision of surface machining

The newest technological solutions related to the stiffness of the machine and a quick feed mechanism provide stable and precise machining.

|

Swing over bed |

550 mm |

|

Maximum diameter of workpiece |

330 mm |

|

Maximum length of element |

500 mm |

|

Maximum weight of element |

200 kg |

|

Chuck size |

8” |

|

Maximum spindle speed |

4000 rpm |

|

Spindle bore |

62 mm |

|

Maximum thorough hole diameter |

51 mm |

|

Spindle taper |

A2-6 |

|

Main motor |

11 kW |

|

X-axis travel |

190 mm |

|

Z-axis travel |

550 mm |

|

X/Z axes quick feed |

30 000; 36 000 mm/min |

|

Chuck type |

servohydraulic |

|

Number of tool holders |

12 |

|

Chuck indexing time |

0.15 s |

|

Maximum tailstock travel |

410 mm |

|

Coolant pump power |

480 W |

|

Dimensions |

2805×1780×1775 |

|

Weight |

3800 kg |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

gross €567.69

A set of folding knives for indexable plates. Complete with Roughing Knife and Inserts, Finishing Knife and Inserts, Grooving and Parting Knife, External Threading Knife and Boring Bar.

gross €530.16

A set of folding knives for indexable plates. Complete with Roughing Knife and Inserts, Finishing Knife and Inserts, Grooving and Parting Knife, External Threading Knife and Boring Bar.

Base for the TYTAN 750 PRO lathe

gross

€666.41

€561.54

The MK4 turret is the perfect equipment for repetitive work requiring more than one tool in the tailstock.

CK7130B CNC Lathe with Inclined Bed

A high-efficiency lathe with a single block bed structure, equipped with a high-precision HIWIN linear guides. The hydraulic chuck and tailstock are included by default and provide stable fastening of heavy and long elements. We also provide machine setup, training for operators and CAD/CAM software.

CK7135AP CNC Lathe with Inclined Bed

gross €37,499.19

This lathe provides not only precise machining but also high X/Z axes positioning repeatability = 0.006 mm (compared to 0.01 mm for ordinary CNC lathes). This is possible due to the factory mounted ball bearings and innovative design solutions implemented in the machine. By default, it comes with a series-array tool holder – stays within the desired place and decreases machining time by as much as 25%.

gross €43,491.49

Our CNC lathe with an inclined bed CK350 is an excellent machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a hydraulic chuck and tailstock ensure secure hold of long and heavy workpieces, making this machine an essential tool for metalworking

gross €42,229.96

Our CNC lathe with an inclined bed CK350 is an excellent machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a hydraulic chuck and tailstock ensure secure hold of long and heavy workpieces, making this machine an essential tool for metalworking.

gross €40,968.42

Our CNC lathe with an inclined bed CK350 is an excellent machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a hydraulic chuck and tailstock ensure secure hold of long and heavy workpieces, making this machine an essential tool for metalworking.

CK7135A CNC Lathe with Inclined Bed

gross

€40,243.04

€33,666.12

This lathe provides not only precise machining but also high X/Z axes positioning repeatability = 0.006 mm (compared to 0.01 mm for ordinary CNC lathes). This is possible due to the factory mounted ball bearings and innovative design solutions implemented in the machine. By default, it comes with a series-array tool holder – stays within the desired place and decreases machining time by as much as 25%.