- Reduced price

The basket is empty.

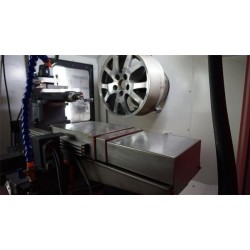

The advanced CNC lathe is an indispensable tool for the refurbishment and precise machining of alloy wheels. The machine enables professional surface finishing, damage removal, and restoring wheels to a like-new appearance.

Equipped with a state-of-the-art CNC control system, the lathe allows for quick programming of machining cycles while ensuring excellent repeatability and high-quality surface finishes.

Its compact dimensions and ergonomic design make it a perfect fit for any workshop space.

This is an ideal choice for professionals seeking an efficient and precise solution for working with alloy wheels.

CORMAK – CNC LATHE FOR ALLOY WHEEL REFURBISHMENT UP TO 32 INCHES

| Specification | Value |

|---|---|

| Maximum turning diameter over bed | 800 mm |

| Maximum turning diameter in bridge gap | 630 mm |

| Spindle nose | A2-6 |

| Spindle bore | 82 mm |

| Chuck | Manual |

| Maximum spindle speed | 1500 rpm |

| Motor power | 6.5 kW |

Equipment (depending on version):

Special wheel chuck for rims up to 32 inches

Software package – wheel profile optimization

Measuring probe

Automatic lubrication system

4-position tool post

Training and technical support fully compliant with CE standards

CNC Controls – Siemens Sinumerik 808D, SINUMERIK 828D, and Fanuc Oi-TF

We offer professional CNC controls from renowned brands Siemens and Fanuc, providing precision, efficiency, and ease of use. Our solutions are ideal for both smaller workshops and demanding industrial applications.

Siemens Sinumerik 808D – Compact CNC Control for Basic Applications

The Siemens Sinumerik 808D is a modern, economical CNC control designed for basic-class lathes and milling machines. The system is tailored for small and medium-sized enterprises, offering:

Intuitive operation – a simple interface based on a graphical display that facilitates machine programming and configuration.

High reliability – robust construction resistant to harsh workshop conditions.

Broad compatibility – suited for machines with basic technological requirements.

An excellent solution for beginner CNC users who want to start working with a modern control system.

Siemens Sinumerik 828D – Advanced Control for Demanding Applications

The Sinumerik 828D is a professional CNC control designed for milling machines and lathes requiring higher precision and performance. Its key features include:

High computational power – fast data processing enables dynamic and precise machining.

Extensive technological functions – advanced machining cycles, interpolation, and tool path optimization features.

Solid, compact construction – built for operation in tough industrial environments.

Easy automation integration – expandable with additional modules and process control options.

CAD/CAM compatibility – seamless cooperation with design software and production management systems.

This is an excellent choice for companies seeking an efficient and reliable CNC control for more complex machining operations.

Fanuc Oi-TF – Stability and Precision in Turning Operations

Fanuc Oi-TF is one of the most popular CNC controls for lathes, known for its reliability and ease of use. This system is widely used in metalworking due to:

Exceptional operational stability – reliable and precise performance even in long-term serial production.

Advanced turning functions – supports various turning cycles including threading, grooving, drilling, and other cutting operations.

Intuitive user interface – quick programming and easy operation thanks to a clear screen and optimized menu.

Wide compatibility – compatible with many lathe machine models.

Efficient process optimization – Fanuc system allows better control over machining parameters, saving time and materials.

With Fanuc Oi-TF, users gain confidence in stable and precise operation, leading to higher productivity and machining quality.

Choosing the right CNC control is crucial for machining efficiency and precision. Siemens Sinumerik 808D is ideal for basic applications, Siemens Sinumerik 828D excels in more demanding production processes, and Fanuc Oi-TF guarantees the highest stability and reliability in turning operations.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Write your review

* Required fields

I accept privacy policy rules