Forklift characteristics

The electric drive ensures quiet, emission-free operation, which allows the truck to be used in closed facilities such as warehouses, logistics centers or production plants with strict environmental standards. The modern power supply system based on traction batteries allows for long-term operation at a low level of energy consumption. Depending on the version, lead-acid or lithium-ion batteries can be used, adapted to individual operational needs.

Forklifts with AGM gel batteries are up to 40% safer than those with lithium-ion batteries, which have a much higher risk of spontaneous combustion. AGM technology is less susceptible to overheating and mechanical damage, which significantly reduces the risk of fire or explosion. In addition, gel batteries do not produce harmful gases and do not require specialist maintenance, making work with them safer and more reliable, especially in demanding warehouse conditions.

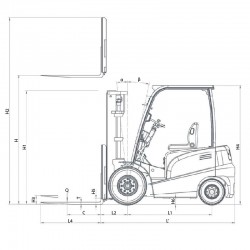

The lifting capacity of 2500 kg allows for effective handling of heavy pallets, containers and other industrial loads. The lifting height of up to 4500 mm allows storage on the upper levels of racks, which increases the efficiency of vertical space use. The mast made of high-quality steel is characterized by high stiffness and resistance to deformation, which affects the stability of work at maximum load.

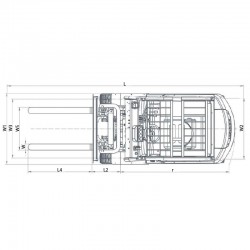

The truck is equipped with a drive and hydraulic system that allows for smooth maneuvering and precise lifting and lowering of the load. Compact external dimensions and an optimal turning radius make it easy to move in narrow work corridors. Support systems – such as automatic speed limit when turning, mast tilt control or soft start function – increase safety and control over the device.

The fork side shift mechanism (so-called side shift) is an element that significantly affects the efficiency of reloading operations. It allows for minor corrections of position without the need to move the entire truck. It allows for precise positioning of the pallet in a limited space, which translates into shorter working cycle times and reduced risk of damage to shelves and goods. This function is becoming an indispensable standard wherever speed and accuracy count.

The manual fork spacing adjustment system allows for quick adjustment of their position to the dimensions of the transported goods. This is a universal solution that allows efficient handling of loads with non-standard dimensions without the need to replace equipment. The solid fork construction and easy-to-use manual adjustment system ensure durability and ease of use.

The mast construction with adjustable angle of inclination allows for effective maneuvering of the load. The forward tilt makes it easier to precisely place the pallet, while the backward tilt of the mast increases the stability of the transported load during transport. This solution increases the level of safety at work, especially when moving on uneven terrain or with full lifting capacity.

The forklift is equipped with pneumatic wheels, which are characterized by excellent shock absorption and increased adhesion to the ground. Thanks to the air filling, this type of tire effectively dampens vibrations generated when driving on uneven or unpaved terrain, which translates into higher comfort for the operator and less wear of the truck's components.

Pneumatic wheels work great in various conditions - both outside and inside industrial facilities. They provide stable maneuvering and reliable handling even on surfaces with reduced grip, such as wet concrete, asphalt or paving stones.

The increased wheel diameter and deep tread facilitate work on loading areas, ramps and in reloading zones with variable terrain.

The truck is equipped with complete work lighting, which provides good visibility when working in poorly lit halls, loading areas or in conditions of variable external lighting. The reflectors emit an intense, bright beam of light, which improves the comfort of operating the mast and load without excessive energy (or fuel) consumption.

The standard equipment also includes warning lights and audible signals, which increase safety in a busy work environment. A reversing alarm, strobe light (rooster) and indicators inform the surroundings about the machine's movement, reducing the risk of collisions in crowded warehouse corridors.

Thanks to the well-thought-out arrangement of light points, the truck provides not only visibility for the operator, but also the visibility of the vehicle itself for other participants in the internal traffic.

Included:

- built-in batteries

- 70A charger

Technical parameters

| Load capacity |

2500 kg

|

| Fork height raised |

4500 mm |

| Fork height lowered |

40 mm |

| Fork length |

1220 mm |

| Slide side |

Yes |

| Mast tilt |

Yes |

| Battery voltage/rated capacity |

48V 490Ah

|

| Continuous operation time on charged battery |

up to 10 h |

| Charging time |

10 h |

| Travel speed with/without load |

12 / 13 km/h |

| Wheel type |

Pneumatic |

| Weight |

4015 kg |