Technical parameters

| Max. thickness of cut sheet metal (S235) |

up to 4.0mm |

| Maximum length of cut sheet metal |

4000mm |

| Cutting angle |

1.5° |

| Number of strokes per minute |

6-20 |

| Rear bumper departure |

600mm |

| Engine power |

5.5kW |

| Length |

4700mm |

| Width |

1850mm |

| Height |

1700mm |

| Weight |

6500 kg |

Equipment:

-

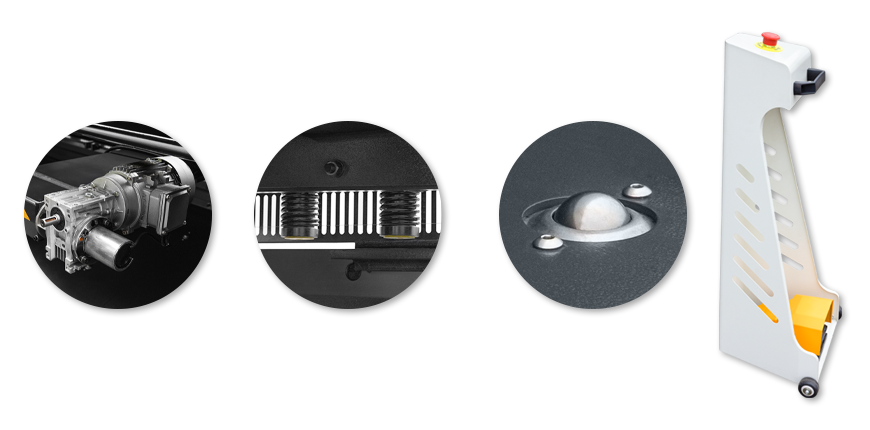

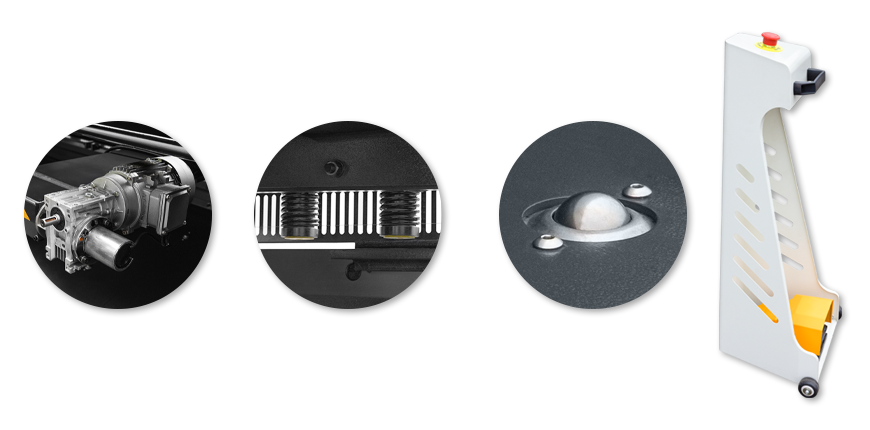

Rear bumper driven by electric motor (on ball screws)

-

Hydraulic sheet metal clamps along the entire cutting length

-

Adjusting the gap between the knives

-

Ball sheet guides on the table

-

Workspace lighting

-

Front bottom brackets

-

Mobile foot controller

Rear ramp:

The rear ramp is equipped with ball guides, which ensures smooth and precise movement of cut-off elements. Thanks to this, no fragment of material remains on the machine, which increases efficiency and safety of work.

Controls and Functionality:

ESTUN E21S

- Controls: Precise rear bumper adjustment.

- Program memory: Up to 40 programs can be stored, each with a maximum of 25 steps.

- Retract function: Automatically retracts the backgauge after cutting.

- Saving parameters: One-touch saving of settings.

- Data protection: Retention of parameters in the event of a power failure.

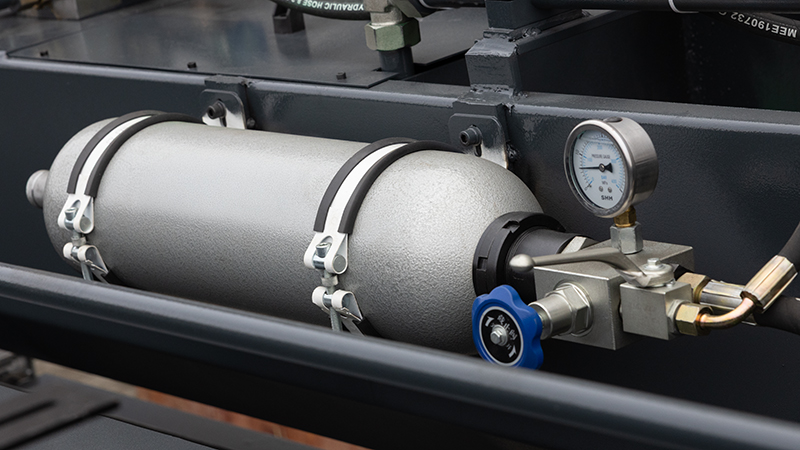

Steel hydraulic connections

The use of steel pipes in hydraulic systems instead of flexible rubber hoses significantly increases the tightness of the system and minimizes the risk of leaks in the future. Thanks to their stiffness and resistance to mechanical damage, steel pipes ensure the durability and reliability of hydraulic connections.

Ergonomics

Thanks to the mobile controller and the controller placed on the movable arm, the operator gains full freedom of action in the entire working area of the machine. Additional LED lighting and a laser pointer provide excellent visibility of the processed elements, which translates into precision and comfort of work in all conditions.

Security

With the safety of operators and employees in mind, our guillotine shears are equipped with a number of solutions to minimize risks during work:

- Clear warning signs

- Solid guards to protect cutting areas

- Rear light gate

- Easily accessible emergency stops

Each machine is supplied with an instruction manual in Polish, which ensures full understanding of the principles of use and maintenance. Additionally, our devices have a CE declaration of conformity, confirming compliance with European safety and quality standards.

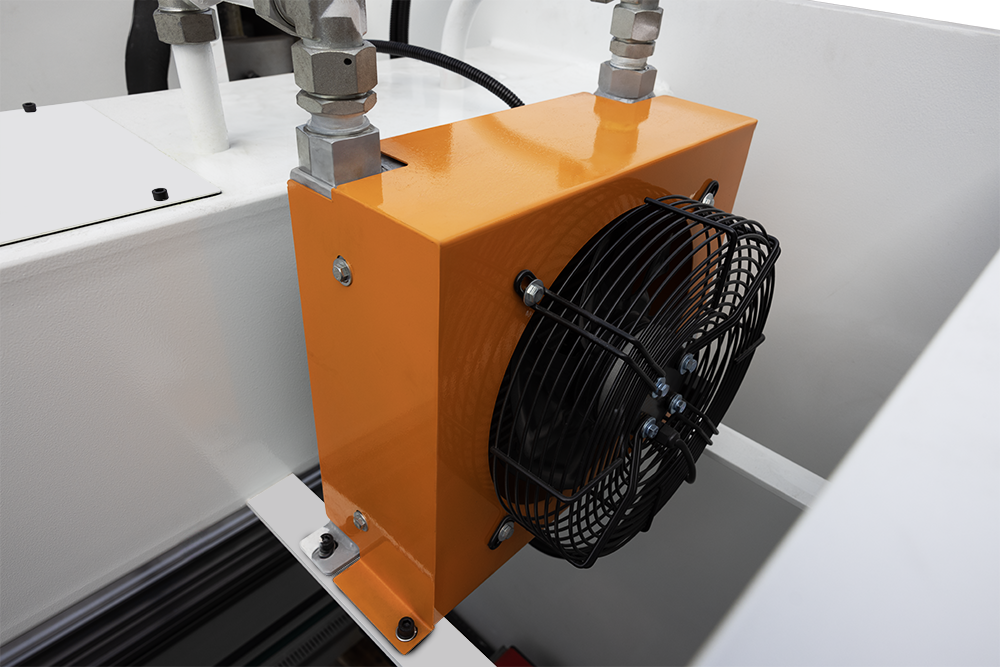

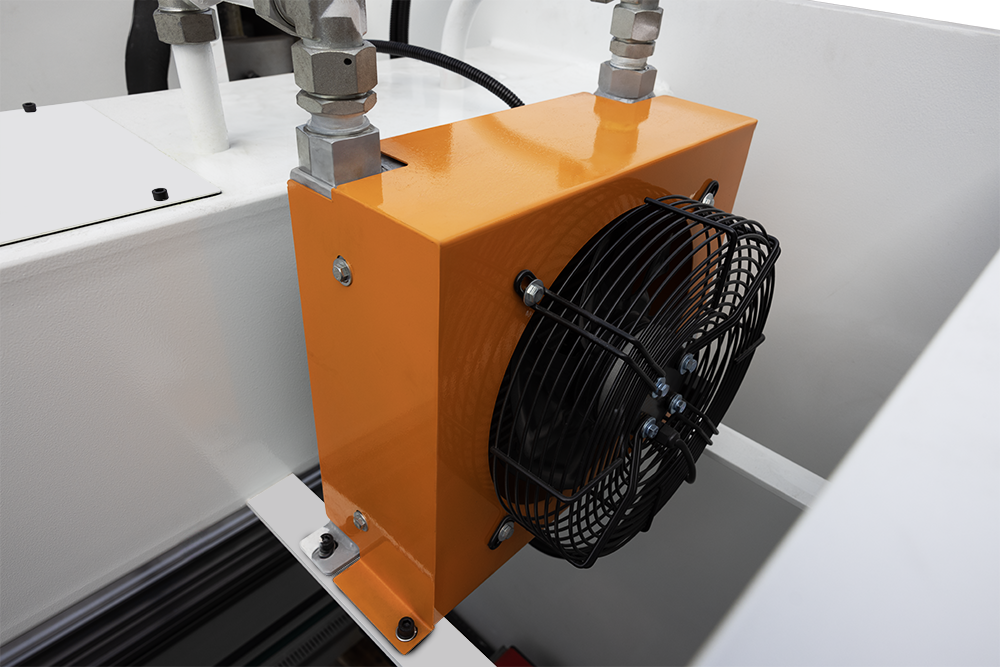

SCO – Oil Cooling System

Our standard system guarantees the stability of the machine's operating parameters even after long, continuous use.

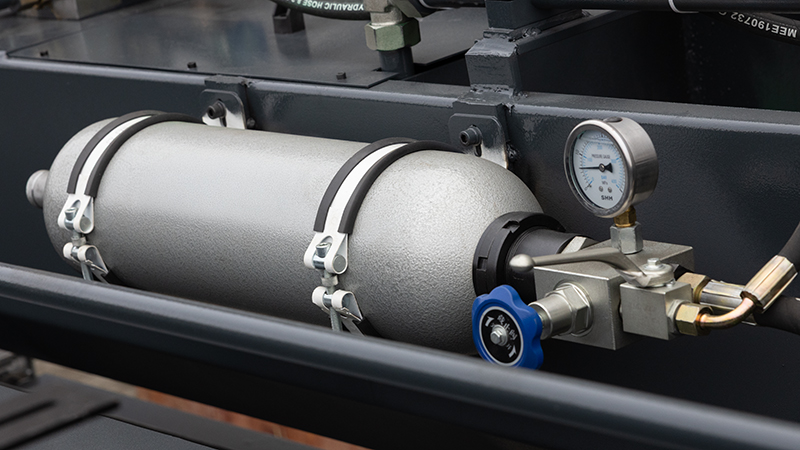

SKC – Pressure Control System

The pressure control system guarantees reliable blade operation for many years.

Included in the price of the machine

Training up to 3 days including machine installation

- Day 1 – machine installation and learning how to operate the controller.

- Day 2 – independent work on the machine under the supervision of our technician – possibility of programming specific details that the Client makes.

- Day 3 – an additional day of training to be used within 12 months – if questions arise during machine operation.

Telephone consultations with a specialist

You can always count on help from a specialist.

Terms of cooperation

- Warranty: 24 months.

- The machine is brand new

- Warranty and post-warranty service provided by the seller

Write your review

* Required fields

I accept privacy policy rules