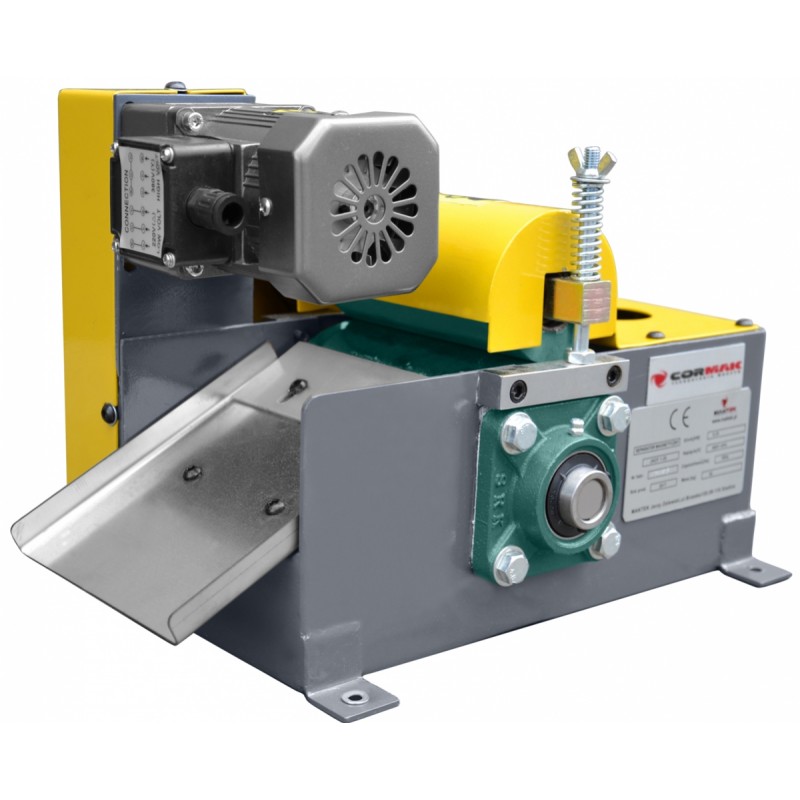

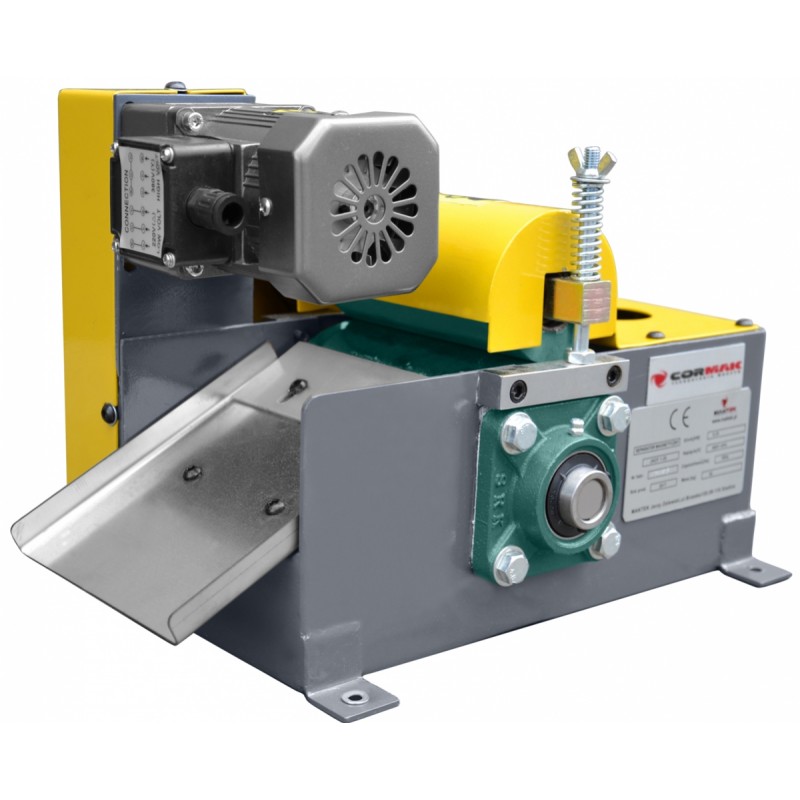

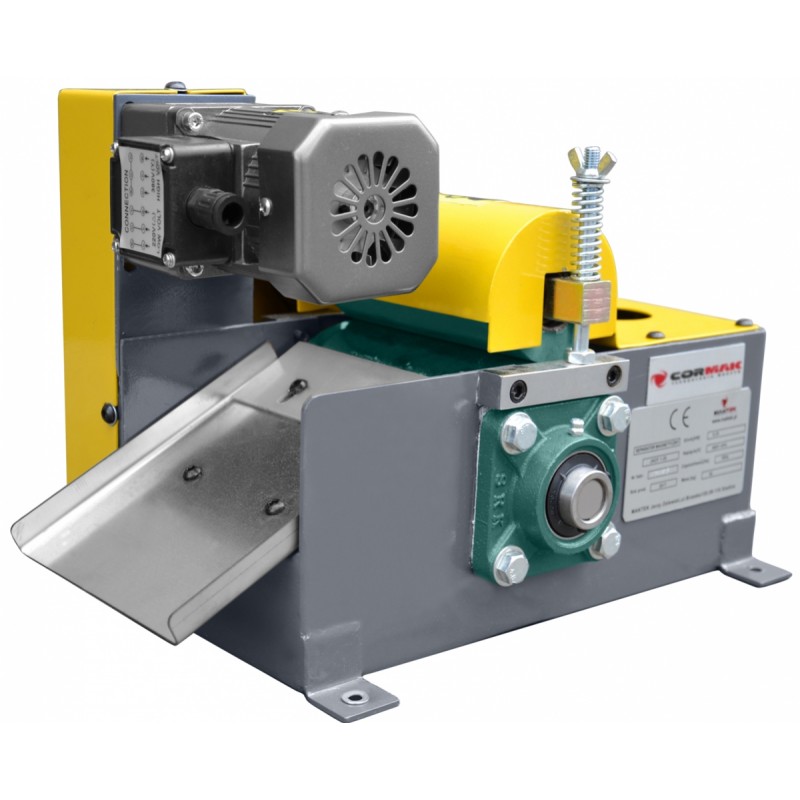

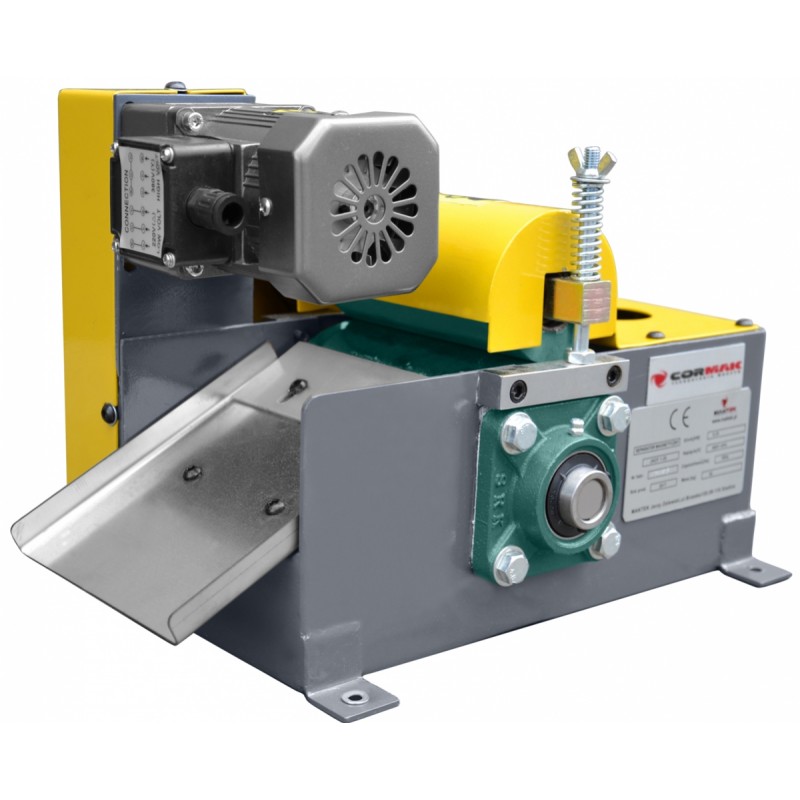

The magnetic separator is used to purify the coolant and oily substances. The separator can continuously remove metal chips from the flowing coolant and empty them into a waste container. It is an ideal solution for technological halls, production lines where machining and grinding with a water or oil-based coolant are used.

The magnetic separator is used to clean the coolant and oily substances. It mainly consists of stainless steel magnetic drum, rubber drum, reservoir. The separator can continuously remove metal chips from the flowing coolant and empty them into a waste container. It is an ideal solution for technological halls, production lines where machining and grinding with a water or oil-based coolant are used. Provides increased productivity with less machine downtime for changing the coolant.

| PRESSURE SHAFT (RUBBER) WIDTH | 140 mm |

| DIAMETER OF PRESSURE SHAFT (RUBBER) | 65 mm |

| MAGNETIC SHAFT WIDTH | 140 mm |

| DIAMETER OF MAGNETIC SHAFT | 110 mm |

| INPUT CONNECTION | 50 mm |

| OUTPUT DIAMETER | 53 mm |

| MOTOR POWER | 0.25 kW |

| PERFORMANCE | up to 25 l / min |

| WEIGHT | 35 kg |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Magnetic separator JHCF1-25

The magnetic separator is used to purify the coolant and oily substances. The separator can continuously remove metal chips from the flowing coolant and empty them into a waste container. It is an ideal solution for technological halls, production lines where machining and grinding with a water or oil-based coolant are used.

The magnetic separator is used to purify the coolant and oily substances. The separator can continuously remove metal chips from the flowing coolant and empty them into a waste container. It is an ideal solution for technological halls, production lines where machining and grinding with a water or oil-based coolant are used.

Write your review

* Required fields

I accept privacy policy rules