- Reduced price

- New

A modern device based on FIBER technology, designed for welding various types of metals, offers precision that significantly exceeds traditional welding methods. Thanks to the 3-in-1 function enabling welding, cutting and laser cleaning, it is versatile and effective in many applications. Advanced technological solutions allow for repeatable, high-quality welding welds on thin-walled materials and parts, minimizing the risk of their deformation.

| Maximum power | 2000 W |

| Laser wavelength | 1080nm |

| Penetration depth (stainless steel 1 m/min) | 4.57mm |

| Penetration depth (black steel 1 m/min) | 3.59mm |

| Remelting depth (aluminum 1 m/min) | 4.0mm |

| Remelting depth (brass 1 m/min) | 4.0mm |

| Welding speed | 0-120mm/s |

| Automatic wire feeder | Ø 0.8 - 1.6 mm |

| Maximum power consumption | ≤6.0 kW |

| Cooling system | water |

| Working voltage | 400V |

| Shielding gas consumption | 20 L/min |

| Dimensions | 600 x 1100 x 1100 mm |

| Weight approx. | 185 kg |

THICKNESS OF WELDED MATERIALS |

||||

| Material |

WELDING POWER |

|||

| 1000W | 1500 W | 2000 W | 3000W | |

| stainless steel | 0.5-3.0mm | 0.5-4.0mm | 0.5-5.0mm | 0.5-8.0mm |

| black steel | 0.5-2.5mm | 0.5-3.5mm | 0.5-4.5mm | 0.5-8.0mm |

| galvanized steel | 0.5-1.2mm | 1.5-1.8mm | 1.5-4.0mm | 1.5-7.0mm |

| Aluminum | 0.5-1.2mm | 1.5-1.8mm | 1.5-4.0mm | 1.5-7.0mm |

| Brass | 0.5-1.2mm | 1.5-1.8mm | 1.5-2.5mm | 1.5-4.0mm |

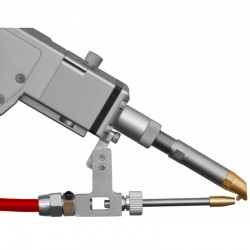

LATEST GENERATION WELDING HEAD

Automatic wire feeder included;

Adjustable spot size 0-5mm;

High-power welding head

Integrated connections for shielding gases and cooling system,

Replaceable nozzles allow welding at different angles,

7 m of optical fiber that connects the head to

Full ergonomics - thanks to the light and flexible design, the head can perform welds even in hard-to-reach places;

Easy to service - quick and trouble-free replacement of the protective lens.

The set includes an automatic wire feeder

The wire feeding system is synchronized with the welding machine software. The task of the feeder is to feed the filling so that the operator can focus 100% on working with the head.

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CORMAK WL2000 laser welding machine

gross

€19,923.06

€14,563.83

A compact device using FIBER technology, designed to weld many types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in the offered welder allow for high-quality, repeatable welding of thin-walled materials and parts without the risk of their deformation.

CORMAK WL1500 laser welding machine

gross

€16,256.39

€11,666.40

A compact device using the FIBER technology, designed for welding many types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in the offered welding machine allow to perform high-quality and repeatable welding welds of thin-walled materials and parts without the risk of deformation.

CORMAK Desktop1500 automatic laser welding machine

gross

€34,376.89

€29,974.07

Laser welding is a fast, precise and high-quality method of joining materials. High-energy laser pulses are used to locally heat the material, creating durable and aesthetic welds. Thanks to the small heat affected zone, deformations are minimal and the welds are uniform and repeatable. Laser welding is ideal for small-sized components and provides high efficiency and low operating costs. Control systems such as Desktop 1500 enable precise control of the welding process, and automation makes work easier. This is an ideal solution for industries where precision and high quality welding are crucial.