- Reduced price

Laser welding is a fast, precise and high-quality method of joining materials. High-energy laser pulses are used to locally heat the material, creating durable and aesthetic welds. Thanks to the small heat affected zone, deformations are minimal and the welds are uniform and repeatable. Laser welding is ideal for small-sized components and provides high efficiency and low operating costs. Control systems such as Desktop 1500 enable precise control of the welding process, and automation makes work easier. This is an ideal solution for industries where precision and high quality welding are crucial.

Laser welding involves using high-energy pulses emitted by a laser to locally heat the material in a small area. As a result of this heating, the material melts, creating a characteristic pool of molten material. This method can be used to weld delicate and precise parts made of thin materials. The welding process is fast and deformations at the joint are minimal. The weld seam is of high quality and the welding process can be precisely controlled, allowing for easy automation.

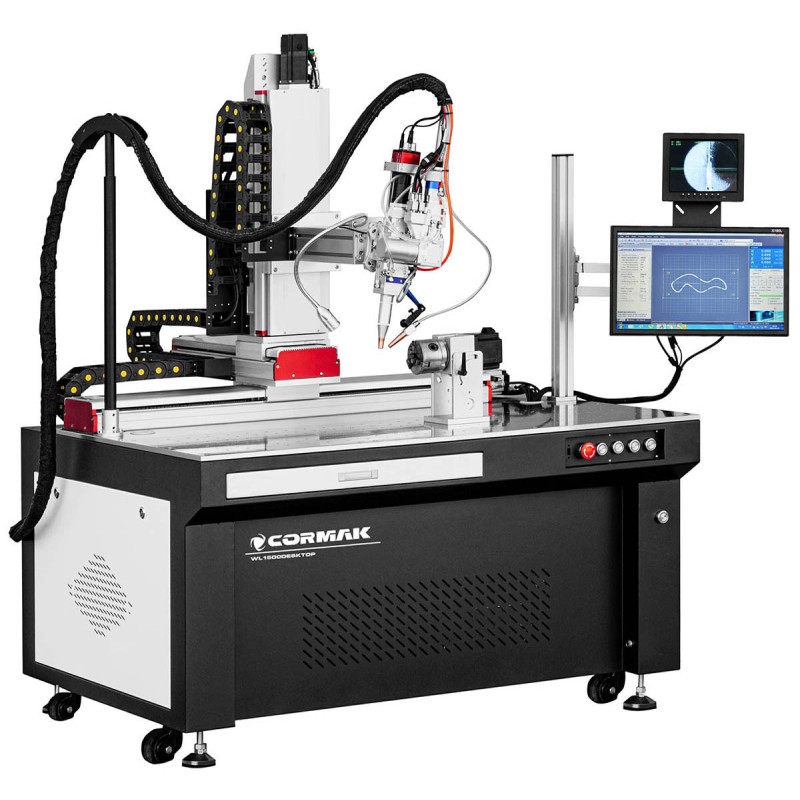

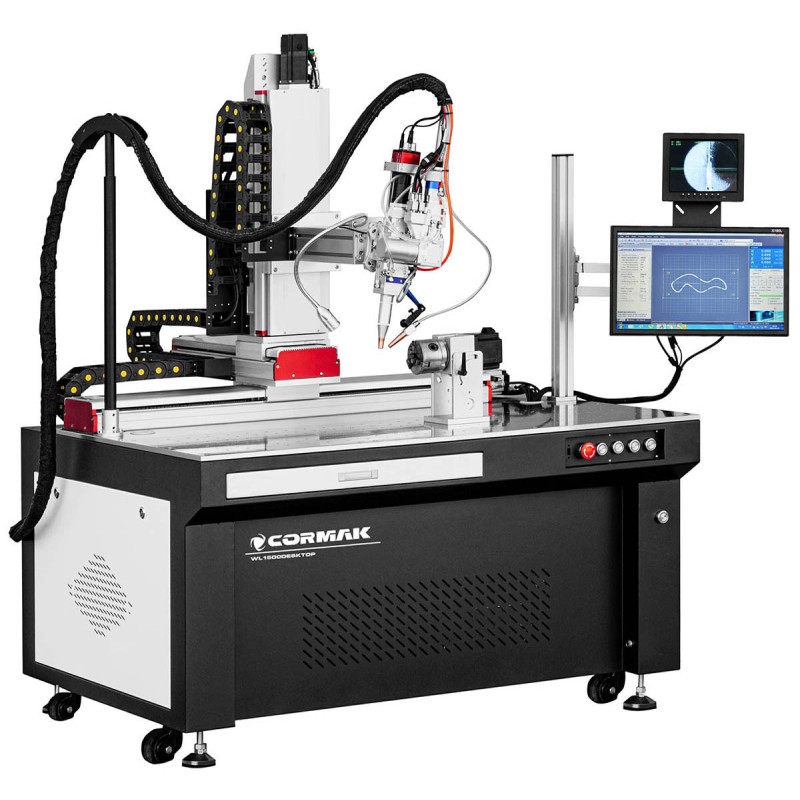

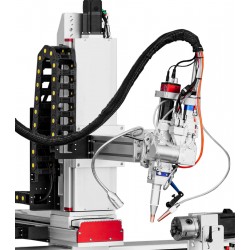

Desktop 1500 is an advanced four-axis control system designed specifically for laser welding. This device is controlled by a computer, enabling automatic or semi-automatic execution of connecting welds and sealing welding. This system allows welding on flat surfaces, along lines, arcs and in any shape.

The welding machine is equipped with a large, automatic work table with four axes, and the two-axis XY platform module is electrically controlled. The Z axis uses a brake motor with power cut-off function. This allows you to accurately weld metal products with unusual shapes. The automatic welding system is widely used in the industry for continuous laser welding, ensuring high quality welds even on the most complex metal elements. It is possible to weld various types of metals, including non-ferrous metals, aluminum, stainless steel and carbon steel.

| Laser Power: | 1500 W |

| XYZ axis movement range: | 730 / 300 / 290 mm |

| Table dimensions: | 1150 x 500 mm |

| Base dimensions: | 1300 x 1000 mm |

| Power supply: | 230V / 10 kW |

| Libra: | 325 kg |

| Dimensions: | 1600 x 1400 x 1650 mm |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CORMAK SL2000 3in1 Laser Welding Machine

gross

€19,923.06

€14,563.83

A modern device based on FIBER technology, designed for welding various types of metals, offers precision that significantly exceeds traditional welding methods. Thanks to the 3-in-1 function enabling welding, cutting and laser cleaning, it is versatile and effective in many applications. Advanced technological solutions allow for repeatable, high-quality welding welds on thin-walled materials and parts, minimizing the risk of their deformation.

CORMAK WL2000 laser welding machine

gross

€19,923.06

€14,563.83

A compact device using FIBER technology, designed to weld many types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in the offered welder allow for high-quality, repeatable welding of thin-walled materials and parts without the risk of their deformation.

CORMAK WL1500 laser welding machine

gross

€16,256.39

€11,666.40

A compact device using the FIBER technology, designed for welding many types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in the offered welding machine allow to perform high-quality and repeatable welding welds of thin-walled materials and parts without the risk of deformation.