- Reduced price

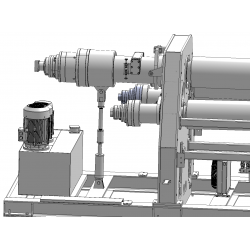

Hydraulic three-roller (3-roller) RMH 2050/500 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 55 mm thick and 2050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production.

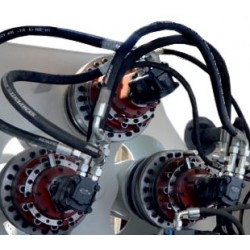

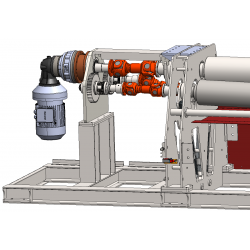

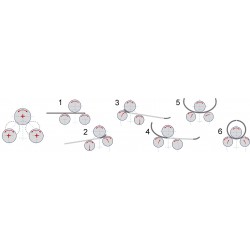

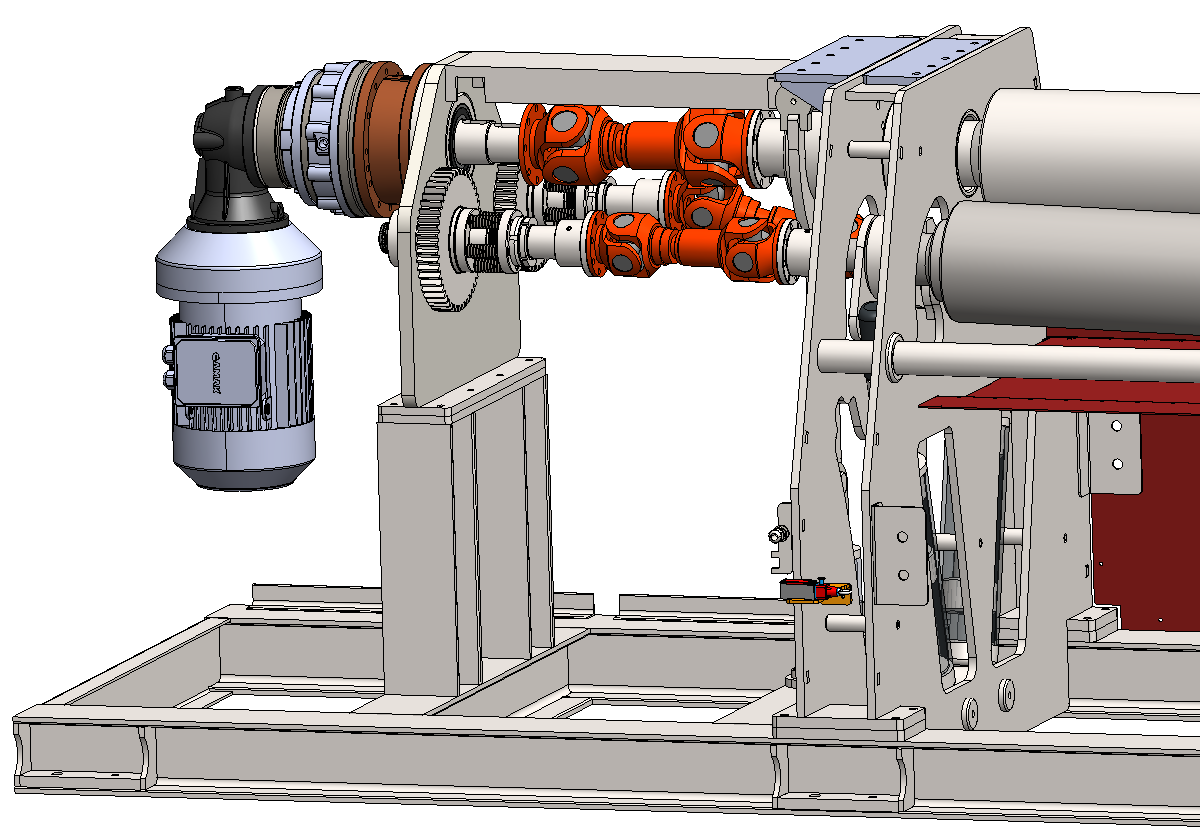

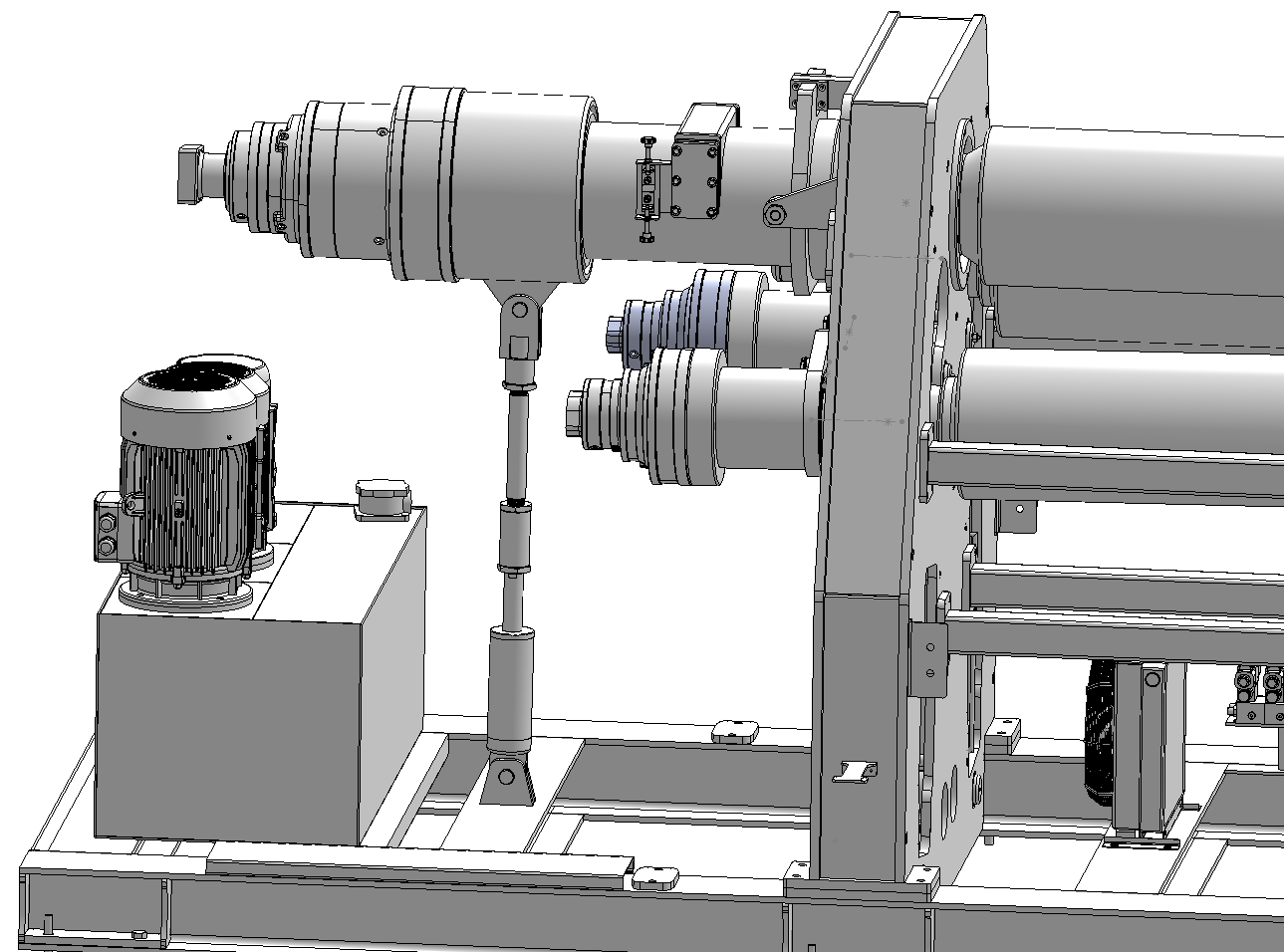

The RMH series hydraulic rolling mill has symmetrically arranged rolls in a pyramidal arrangement. This makes it possible to perform preliminary and conical bending. Most of the torque is generated by the hydraulic drive of all three rollers via a high-performance planetary gear. This ensures direct transfer of force to the roll and maximum power without losses.

The hydraulic, three-roller rolling mill has a pyramidal arrangement. The bending radius is changed using the side rollers, and the upper roller is responsible for feeding the sheet left and right.

|

|

| Three hydraulically driven rollers | Digital display of side roller positions |

| ROLLER PARAMETERS |

|

| ROLLER LENGTH | 2050 mm |

| CENTRAL CYLINDER DIAMETER | Ø< /span>500mm |

| DIAMETER OF SIDE ROLLERS | Ø < /span>480mm |

| WITH PRE-BENDING | |

| MAXIMUM SHEET THICKNESS / MINIMUM BENDING DIAMETER | 40 mm / Ø 75 |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Hydraulic three-roll rolling mill (3-roller) RMH 2550/300 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 18 mm thick and up to 2550 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

gross

€100,220.41

€96,374.26

Hydraulic three-roller (3-roller) RMH 2550/320 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 20 mm thick and 2550 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

gross

€53,846.10

€51,871.74

Hydraulic three-roll rolling mill (3-roller) RMH 2050/240 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 15 mm thick and up to 2050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roll rolling mill (3-roller) RMH 2550/350 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 25 mm thick and 2550 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

gross

€56,897.38

€54,846.10

Hydraulic three-roll rolling mill (3-roller) RMH 2550/240 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 12 mm thick and up to 2550 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roll rolling mill (3-roller) RMH 2050/350 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets with max. thickness up to 30 mm and width up to 2050 mm. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roller (3-roller) RMH 2050/420 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 40 mm thick and 2050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production.

gross

€66,743.52

€64,179.42

Hydraulic three-roll rolling mill (3 rolls) RMH 2050/280 is a machine with increased power, reinforced and rigid structure and high performance. It is used to produce cylindrical and conical forms from the thickest sheets. The rolling machine is designed for bending sheet metal up to 18 mm thick and 2050 mm wide. Hydraulic 3-roll rolling machines of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roll rolling mill (3-roller) RMH 4100/380 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 16 mm thick and up to 4100 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production.

Hydraulic three-roll rolling mill (3-roller) RMH 4100/420 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 20 mm thick and 4100 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roll rolling mill (3-roller) RMH 4100/320 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 10 mm thick and up to 4100 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roller (3-roller) RMH 2050/460 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 50 mm thick and 2050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

gross

€62,048.66

€59,794.81

Hydraulic three-roller (3-roller) RMH 3050/210 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 7 mm thick and 3050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roller (3-roller) RMH 3050/550 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 50 mm thick and 3050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

gross

€54,333.28

€52,282.00

Hydraulic three-roll rolling mill (3-roller) RMH 2550/210 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 10 mm thick and up to 2550 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Hydraulic three-roll rolling mill (3-roller) RMH 3050/350 is a machine with increased power, reinforced and rigid structure and high efficiency. It is used to produce cylindrical and conical forms from the thickest sheets. This model is designed for bending sheets up to 20 mm thick and 3050 mm wide. Hydraulic rolling mills of the RMH series are perfect for industrial plants in serial and large-scale production. Hydraulic sheet roll bender intended for serial and unit production.

Write your review

* Required fields

I accept privacy policy rules or Cancel