- On sale!

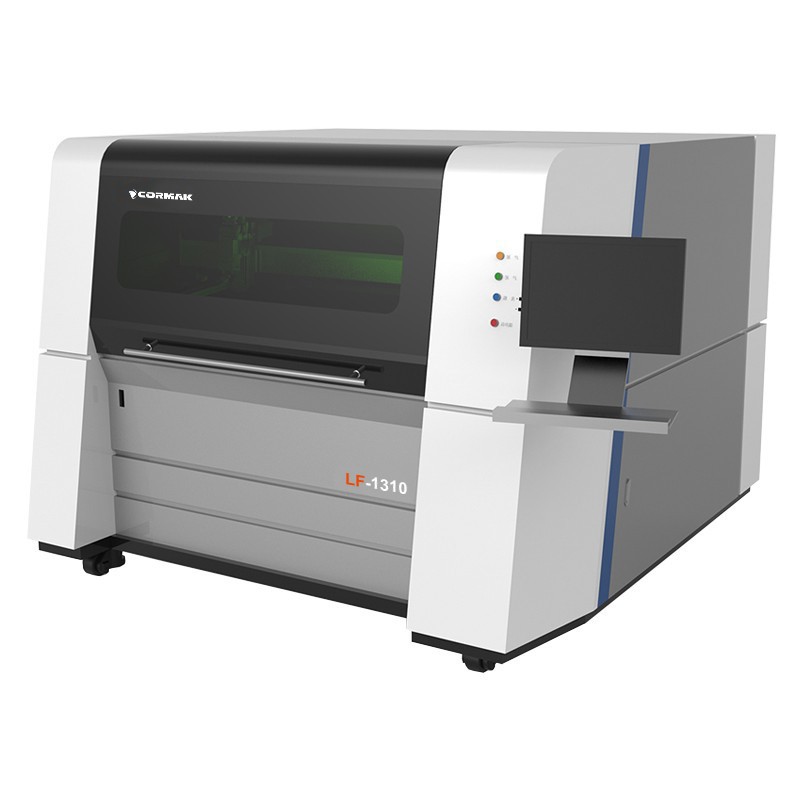

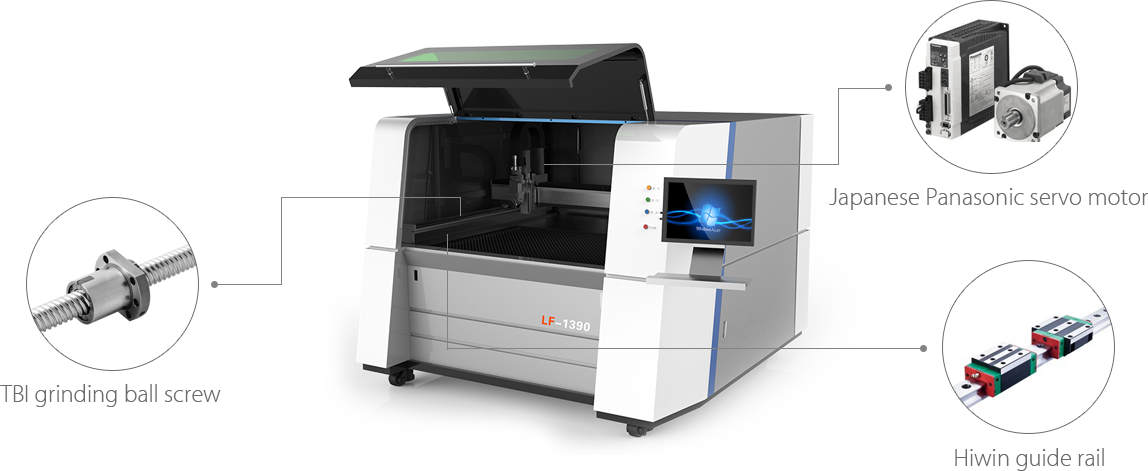

A laser cutter with unparalleled cutting precision. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies with all safety standards, providing effective protection during the operation of the laser cutter.

Optical fiber laser cutters constitute modern devices with many advantages. These are not only a perfect and more profitable alternative to the CO2 technology, but they also possess a lot of pros by themselves, such as improving the production by considerable margin and increasing its quality. FIBER technology allows for cutting sheets and other materials of various thickness: from very thin to very thick. The length of a wave in a FIBER laser is 1.064 micrometre long. These properties influence the intensity, which is a hundred times higher than in the case of CO2 devices of similar power.

The construction of the sliding gate is made of annealed aircraft aluminium, formed with a strength of 4300 tonnes, achieving unprecedented rigidity. Aircraft aluminium has many advantages: high rigidity (higher than cast iron), small mass, resistance to corrosion and oxidation as well as susceptibility to machining.

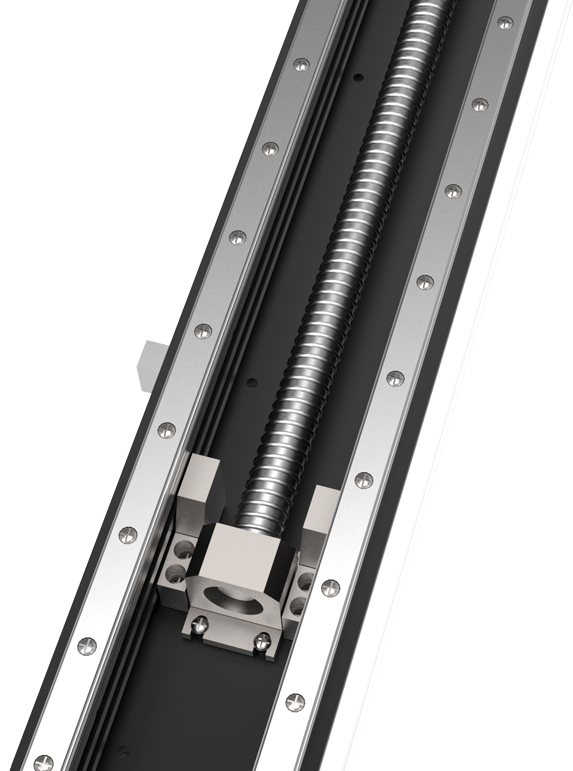

Two guide rails were installed on both sides and a double ball screw ensuring straightness and the precise movement during work with quick cutting.

| Working area | 1300×1000 mm |

| Power | 500W, 750W, 1000W |

| Total power | 10 kW |

| Positioning repeatability accuracy | ± 0.03 mm/m |

| Maximum speed | 40 m/min |

| Maximum acceleration | 0.5G |

| Dimensions | 2110×2160×1630 mm |

| Weight | 1500 kg |

| Power supply | 400V 50Hz |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

FIBER LF1310GEP4 high precision 1500W fiber laser

gross

€51,723.03

€46,046.11

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies with all safety standards and provides effective protection during operation of the laser cutter.

FIBER LF1310GEP4 high precision 2000W fiber laser

gross

€58,030.71

€52,353.79

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies with all safety standards and provides effective protection during operation of the laser cutter

Plate and Tube Fiber Laser cutting machine LF3015GAR

gross

€120,161.42

€112,276.81

A specialized fiber laser that can cut not only metal sheets but also pipes and profiles. High acceleration, high cutting accuracy, pipe turntable and the use of an exchangeable table make this laser cutter unrivaled in comparison to other fiber lasers. One machine, many possibilities. Save with our fiber laser.

FIBER LF3015GA fiber laser - 20000W

gross

€465,191.84

€242,530.53

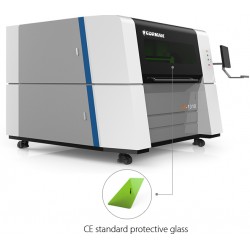

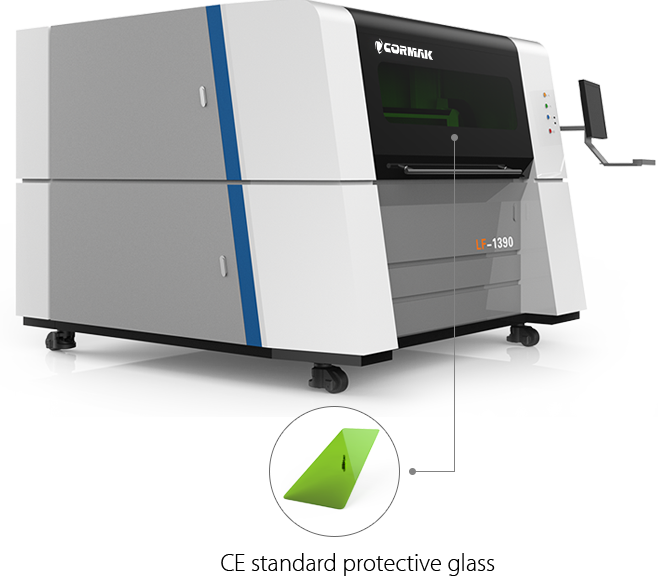

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

gross

€185,761.35

€160,530.61

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

FIBER LF1310GEP4 high precision 3000W fiber laser

gross

€64,338.40

€58,661.48

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies with all safety standards and provides effective protection during operation of the laser cutter.

Whole cover fiber laser cutting machine LF4020GH / LF6025GH 20000W

The fiber laser is equipped with linear motors, thanks to which it achieves enormous cutting speeds. The 20kW laser source is suitable for cutting boards up to 70 mm thick. The applied modern solutions allow you to significantly save time and increase the efficiency and effectiveness of work.

gross

€131,830.64

€114,799.89

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Whole cover laser fiber cutting machine LF3015GA/LF4020GA

gross

€95,561.44

€67,807.62

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Laser fiber cutting machine LF4020GEP

gross

€104,707.59

€77,899.92

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Laser fiber cutting machine LF3015GEP

gross

€76,953.77

€64,338.40

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 12000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Laser fiber cutting machine LF3015GA 12000W

gross

€183,553.66

€157,376.77

Modern, fully built-in fiber laser with a power of 12kW for cutting metal sheets with dimensions of 3000x1500 mm. Thanks to the high power of the laser, we get faster cutting and thus lower energy and gas consumption. Reinforced construction of the laser and additional thermal shields guarantee safety of use.

Large format whole cover fiber laser cutting machine LF12025GH / LF10025GH 20000W

The super fast large format fiber laser is ideally for use in industry. Due to a 20kW laser source, it is suitable for cutting boards with a thickness of up to 70 mm. The modern solutions used allow to significantly save time and increase the efficiency and effectiveness of work.

FIBER LF3015GEP 4000W fiber laser IPG Germany

gross

€103,761.43

€94,930.67

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve the efficiency and comfort of work. The offer includes a laser with a power from 1000W to 12000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

FIBER LF3015GEP 6000W fiber laser

gross

€114,799.89

€106,915.28

A modern, fully built-in fiber laser for cutting sheet metal. The laser housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power ranging from 1000W to 12000W, and the highest quality components ensure long and failure-free use of the fiber laser.