-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

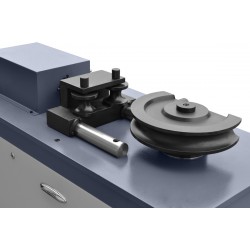

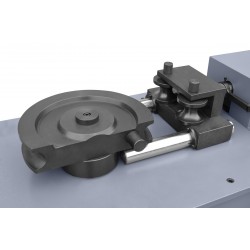

Machine description

The bending machine is equipped with two motors:

- 2.2 kW for rotating the gear with the matrix

- 1.1 kW for operating the hydraulic press pump

The hydraulic pump is responsible for pressing the hoof. In automatic mode the machine independently presses the hoof to the appropriate distance depending on the pipe diameter. The adjustable limit switch allows you to set the appropriate pressure.

The bending machine has 2 operating modes: automatic and manual;

AUTOMATIC MODE

The operator sets the required bending angle of the element on the control panel and then presses the button on the foot controller. The machine then bends the pipe.

MANUAL MODE

In manual mode, the operator manually sets the pipe bending angle (via the control panel).

The panel is equipped with a display that shows the set bending angle and the current pipe bending angle.

Standard equipment

- digital reading of the bending angle

- The BENDMASTER 50 machine is equipped with dies for pipes with a diameter of: 25; 32; 38; 48.3 mm

Technical data

|

MAXIMUM BENDING ANGLE

|

180°

|

|

DIE ROTATIONAL SPEED DURING BENDING

|

5 rpm

|

|

MOTOR POWER MAIN

|

2.2 kW

|

|

HYDRAULIC PUMP MOTOR POWER

|

1.1 kW

|

|

EXTERNAL DIMENSIONS OF THE DEVICE

|

1145 x 580 x 980 mm

|

|

WEIGHT

|

620 kg

|

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

3 other products in the same category:

2024-11-30

Giętarka BRNDMASTER 50

Dobra maszyna. Były zaraz po zakupie pewne problemy, nie z maszyną. Ale giętarka godna polecenia. Ciężka stabilna, wszystko działa tak jak należy. Żeby efekty pracy były pozytywne, należy giętarkę wypoziomować. Godna polecenia. A klientem jestem wymagającym.