- Reduced price

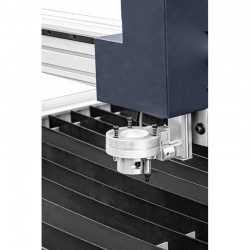

A CNC plasma burner with a water table, a set of a Luft 1000 compressor and a SPARTUS ProCUT 125CNC source is a device intended for shape cutting of elements from sheet metal (in any shape). This machine is characterized by extraordinary simplicity and ease of use. Our CNC cutting machine guarantees repeatability and high cutting accuracy (0.1 mm), thanks to which the burned shapes can be transferred directly to the next stage of production.

The water table ensures low consumption of consumables, raw materials and low gas emissions. No need to use fume and exhaust gas extraction.

Technical parameters of the IZBERG N10S DEHUMIDIFIER |

|

| Engine power | 0.29kW |

| Air outlet and inlet pipe diameter (BSP) | 1" |

| Working in systems for | 10 Bar |

| Inlet temperature | ≤38°C |

| Dimensions | 700 x 420 x 650 mm |

| Efficiency | 1500 l/min |

| Tension | 230V |

| Libra | 45 kg |

| Type and quantity of coolant | R134a, 400 g |

| Supply voltage | ~3 × 400V ± 10% 50 / 60 Hz |

| Cutting current [A] | 20 – 100 |

| Max. cutting thickness [mm] | 55 |

| Duty cycle [%] | 100 |

| PLASMA PARAMETERS | |

| Output operating voltage [V] | 88 - 106 |

| Recommended working pressure [bar] | 5.5 |

| Air demand [l/min] | 250 |

| Post-gas | Yes |

| Contactless arc ignition without HF | Yes |

| 2T/4T | Yes |

| OTHER PARAMETERS | |

| Current consumption [A] | 28 |

| Power factor (cosφ) | 0.76 |

| Efficiency η [%] | 85 |

| Insulation class | H |

| Level of security | IP21S |

| Weight [kg] | 32 |

| Dimensions [mm] | 770×270×490 |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

PW-1530 WTK plasma cutter + Luft 1000 compressor + SPARTUS ProCUT 125CNC source

gross

€20,465.60

€18,878.90

The CNC plasma burner with a water table is a device designed for shape cutting of elements from a sheet of metal (in any shape). This machine is characterized by extreme simplicity and ease of use. Our CNC cutter guarantees repeatability and high cutting accuracy (0.1 mm), thanks to which burnt shapes can be transferred directly to the next stage of production. The water table ensures low consumption of consumables, raw materials and low gas emissions. No need to use fume and flue gas extraction.

PW–1530 WTK 1500x3000 Plasma Cutter with Water Table

gross

€11,669.22

€11,038.45

The CNC plasma burner with a water table is a device designed for shape cutting of elements from a sheet of metal (in any shape). This machine is characterized by extreme simplicity and ease of use. Our CNC cutter guarantees repeatability and high cutting accuracy (0.1 mm), thanks to which burnt shapes can be transferred directly to the next stage of production. The water table ensures low consumption of consumables, raw materials and low gas emissions. No need to use fume and flue gas extraction.

PW-1530 AST 1500x3000 Plasma-Gas Cutter

gross

€8,515.38

€6,906.92

CNC plasma, oxygen-gas burner is a device designed for cutting out shapes from sheets (any shapes). This machine features simplicity and easy handling. Our CNC cutter ensures high accuracy and repeatability of cutting (0.1 mm), allowing for the burned shapes to be transferred directly to the next stage of manufacturing.

PW-1530 AST 1500x3000 plasma and gas burner + Luft 1000 compressor + SPARTUS ProCUT 125CNC source

gross €14,239.67

A CNC plasma burner is a portable device used for precise cutting of elements from sheet metal. Thanks to numerical control (CNC), the machine can create complex shapes with an accuracy of up to 0.1 mm. Burnt elements can be directly used in the further production process. This tool is easy to use and ideal for both large industrial companies and small family workshops.

3000x1500 VolCut Plasma Cutter

gross

€33,115.35

€25,514.59

ONE DEVICE, MULTIPLE CAPABILITIES 2 in 1 – GAS AND PLASMA CUTTING Professionals with over a decade of experience from many fields contributed to the rise of CNC cutters and plotters manufactured in Poland. An extraordinarily important feature of these cutters is the simplicity and ergonomics of operation — due to that there aren’t many days of painstaking training and learning interfaces with foreign languages between the moment of purchase and the start of the production. Additionally, for end users of significance are such aspects as slow wear of consumables, resources and low gas emission, due to the usage of water table.

4000x2000 VolCut Plasma Cutter

gross

€38,476.88

€25,514.59

ONE DEVICE, MULTIPLE CAPABILITIES 2 in 1 – GAS AND PLASMA CUTTING Professionals with over a decade of experience from many fields contributed to the rise of CNC cutters and plotters manufactured in Poland. An extraordinarily important feature of these cutters is the simplicity and ergonomics of operation — due to that there aren’t many days of painstaking training and learning interfaces with foreign languages between the moment of purchase and the start of the production. Additionally, for end users of significance are such aspects as slow wear of consumables, resources and low gas emission, due to the usage of water table.

PW-1530 AST 1500x3000 plasma and gas cutting machine + SPARTUS ProCUT 125CNC source

gross €10,060.76

A CNC plasma burner is a portable device used for precise cutting of elements from sheet metal. Thanks to numerical control (CNC), the machine can create complex shapes with an accuracy of up to 0.1 mm. Burnt elements can be directly used in the further production process. This tool is easy to use and ideal for both large industrial companies and small family workshops.

6000x2000 VolCut Plasma Cutter

gross

€46,361.49

€43,207.65

ONE DEVICE, MULTIPLE CAPABILITIES 2 in 1 – GAS AND PLASMA CUTTING Professionals with over a decade of experience from many fields contributed to the rise of CNC cutters and plotters manufactured in Poland. An extraordinarily important feature of these cutters is the simplicity and ergonomics of operation — due to that there aren’t many days of painstaking training and learning interfaces with foreign languages between the moment of purchase and the start of the production. Additionally, for end users of significance are such aspects as slow wear of consumables, resources and low gas emission, due to the usage of water table.

gross

€5,203.84

€3,768.97

Plasma burner or oxygen-gas CNC burner is a mobile device designed for cutting shapes out of a metal sheet. The machine does not require anchoring, thus reducing the assembly time considerably. Additionally, it enables for placing the machine in any location within the hall without any new expenses.