- Reduced price

The only latest Ucancam V12 software available on the market translated into POLISH

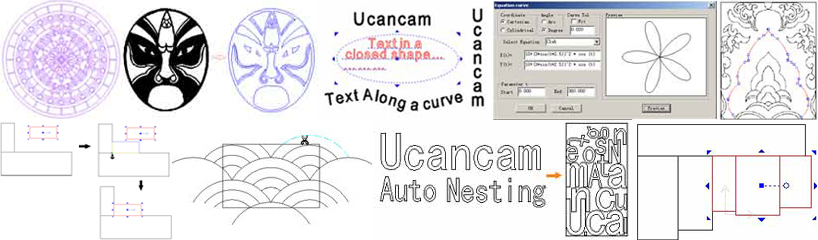

Ucancam V12 PROsoftware for milling plotters is a professional CAD and CAM solution. It is widely used in areas such as advertising, woodworking, decoration production, milling of complex forms (seals, trademarks), or creation of works of art and architectural forms, etc.

For our customers, the latest Ucancam V12 software in Polish is included with our machines!

Ucancam V12 PRO is professional software for industrial applications. Contains all necessary design and processing tools.

It is the best solution for creating 3D models, rapid prototyping and creating signs, carving wood (custom fireplaces, door panels), cutting stone (monuments, commemorative plaques).

Contains extensive CAM and CAD modules enabling the creation of projects from scratch, flexible editing and artistic refinement. It is an advanced yet easy-to-use solution used in many industries, such as carpentry, advertising, decoration and art.

Offers all the tools needed for surface treatment on MDF boards.

Ucancam V12 PRO software for milling plotters is a professional CAD and CAM solution. It has extensive modules that allow you to create a project from scratch, i.e. from a drawing to a ready GCOD interpreted by a CNC machine. It also enables earlier simulation of machining.

The latest version V12 PRO includes:

Allows import of files: .iges, .stl, .obj

It also allows you to import ready-made projects in vector formats: .dxf, .plt, .ai, .eps and bitmap formats: .bmp, .jpg, .tiff, .png.

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

The latest software for CNC milling machines UCanCam V12 Standard CAD/CAM, Polish language version

gross

€422.82

€320.26

The only latest Ucancam V12 software available on the market translated into POLISH Ucancam V12 Standard software for milling plotters is a professional CAD and CAM solution. It is widely used in areas such as advertising, woodworking, decoration production, milling of complex forms (seals, trademarks), or creation of works of art and architectural forms, etc. For our customers, the latest Ucancam V12 software in Polish is included with our machines!

gross €1,766.66

Perfect for any CNC milling machine that requires material holding. Produced in the factory of the renowned BECKER company! The pump creates a vacuum of 440 mbar.

UCannest V12 Demo CAD software

The Ucannest software is software designed to work with many numerically controlled machine tools, such as plasma cutters, water cutters, laser plotters, etc. Download UCannest Demo It is possible to order Ucannest Standard V12 with a license key.

Write your review

* Required fields

I accept privacy policy rules or Cancel