- Reduced price

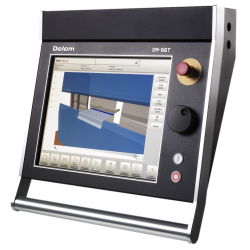

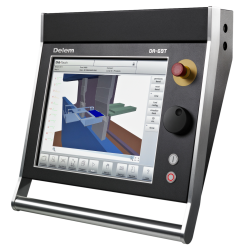

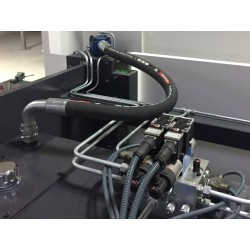

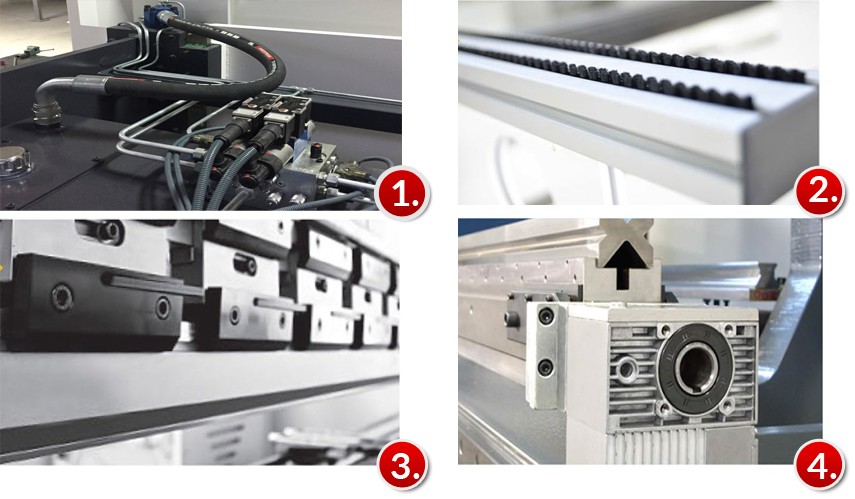

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

| Max. bending length | 4,100 mm |

| Press pressure | 175 tons |

| Jump | 270 mm |

| Distance between columns | 3550 mm |

| Table width | 120 mm |

| Table height | 920 mm |

| Engine power | 18.5 kW |

| Oil tank capacity | 200 l |

| Dimensions (LxWxH) | 5500 x 2250 x 2920 mm |

| Weight | 11,500 kg |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

gross

€81,871.71

€73,684.54

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€103,922.97

€93,530.68

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€122,640.90

€110,376.81

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€75,992.23

€68,393.01

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€114,946.04

€103,451.44

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€101,102.46

€90,992.22

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€95,743.49

€86,169.14

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€151,399.85

€136,259.86

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

gross

€146,984.47

€132,286.02

CNC controlled press brake with 4 CNC axes. The press brake complies with all CE standards, equipped with the "AKAS" system. CNC controlled table deflection compensation - as standard.

Write your review

* Required fields

I accept privacy policy rules or Cancel