- Reduced price

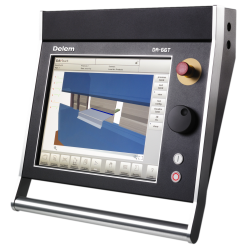

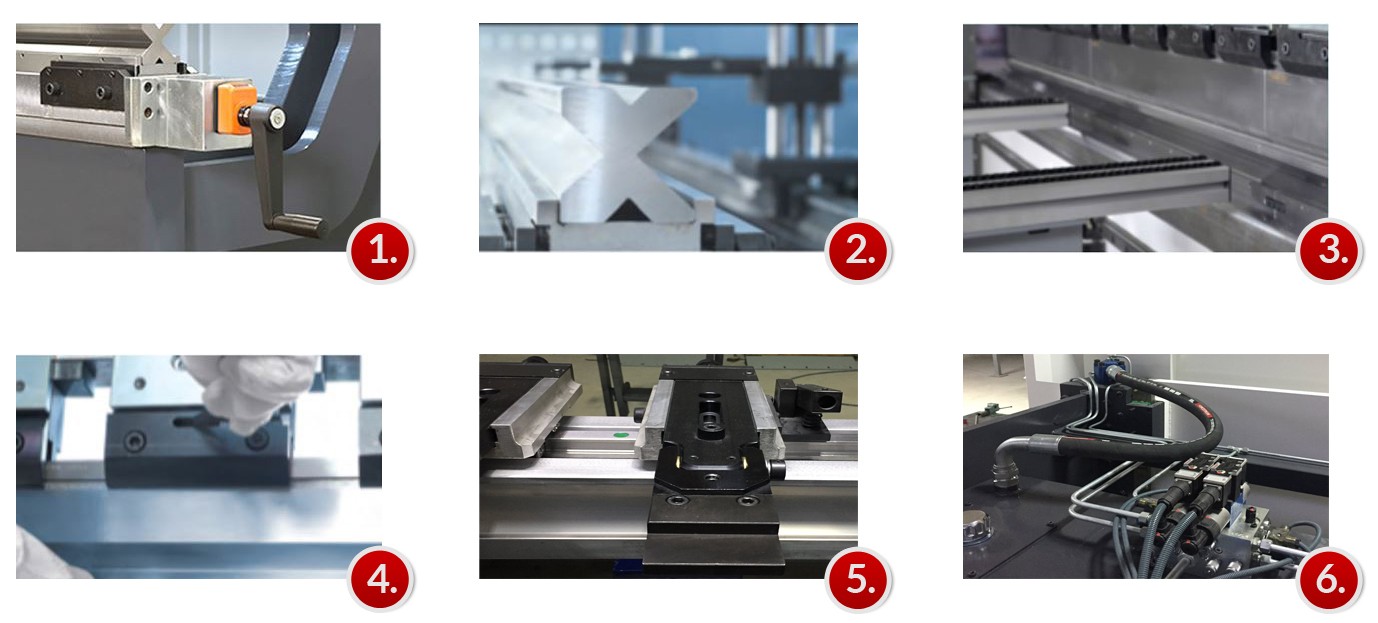

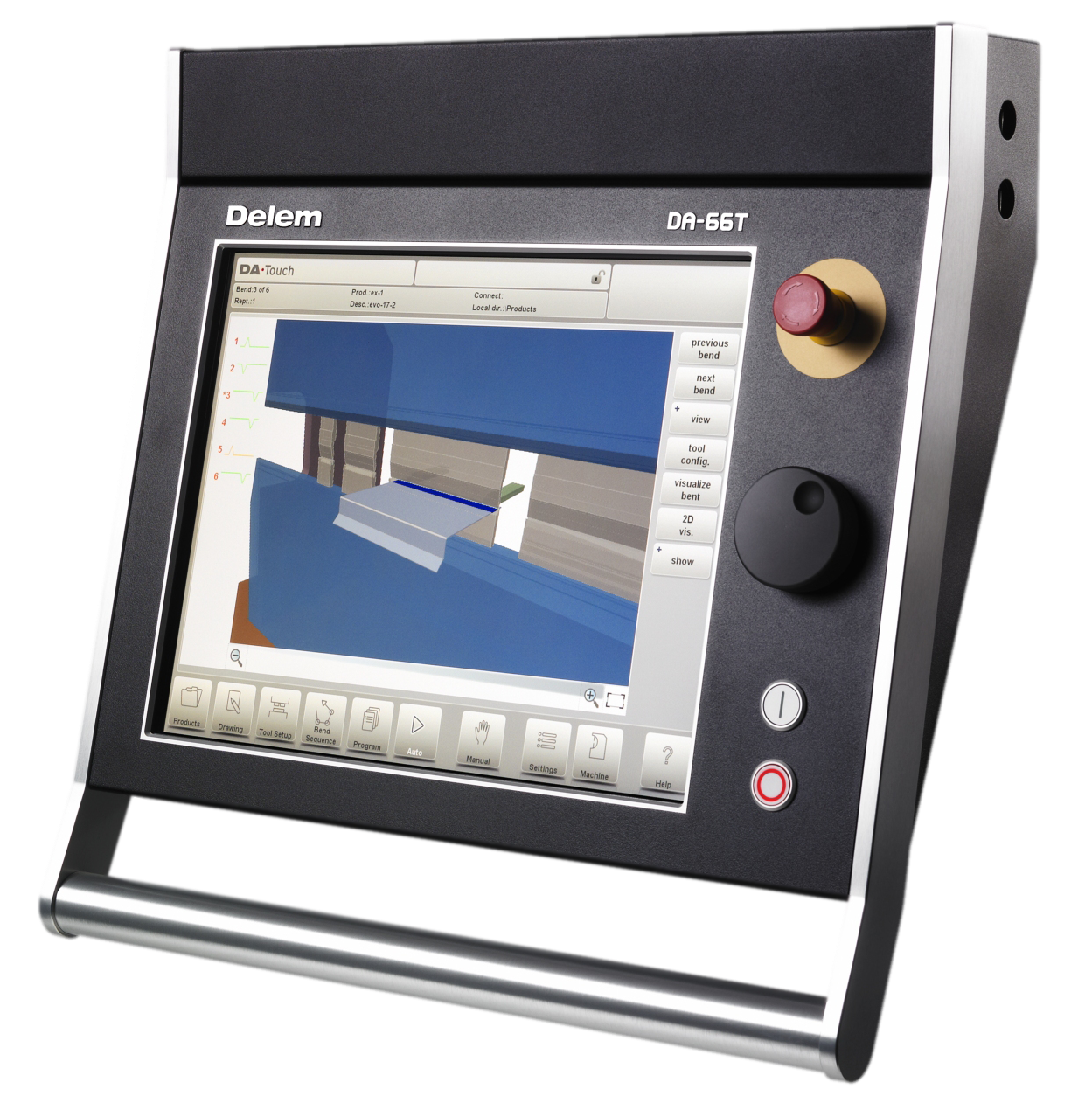

The EASY 31320 CNC press brake is a modern machine for bending sheet metal at any angle. The increased efficiency design allows for precise bending for longer periods of time. The press has three axes: X, Y1 and Y2, CNC control, pressure up to 320 tons and bending length up to 3100 mm.

| Max. bending length | 3100mm |

| Press pressure | 320 tons |

| Jump | 370mm |

| Clearance | 550mm |

| Throat depth | 450mm |

| Distance between columns | 2550mm |

| Table width | 150mm |

| Table height | 920 mm |

| Engine power | 37 kW |

| Oil tank capacity | 300 l |

| Dimensions (LxWxH) | 4400 x 2550 x 3100 mm |

| Libra | 13,500 kg |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

The EASY 61220 CNC press brake is a state-of-the-art machine for bending sheet metal at any angle. The increased capacity design allows the machine to maintain precise bending for longer runs. The press has three axes: X, Y1 and Y2, CNC control, a pressure of up to 220 tonnes and a bending length of up to 6100 mm.

Press Brake CORMAK EASY 31320 (4-axis)

gross

€146,999.85

€132,299.87

The EASY 31320 CNC press brake (4-axis) is a modern machine for bending sheet metal at any angle. The increased efficiency design allows for precise bending for longer periods of time. The press has four axes: X, Y1, Y2, R, CNC control, pressure up to 320 tons and bending length up to 3100 mm.

gross

€118,987.06

€113,037.71

EASY 41175 CNC press brake is a modern machine for bending sheet metal at any angle. The increased efficiency design allows for precise bending for longer periods of time. The press has three axes: X, Y1, Y2, CNC control, pressure up to 175 tons and bending length up to 4100 mm.

Write your review

* Required fields

I accept privacy policy rules or Cancel