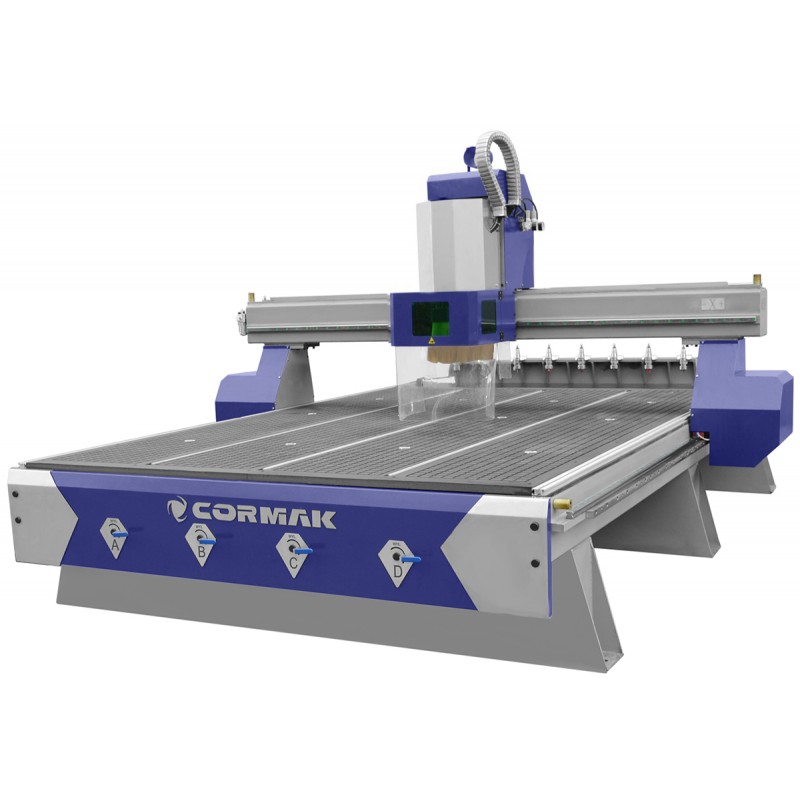

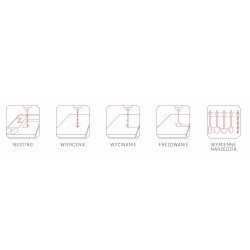

Machine features

1. Worktable

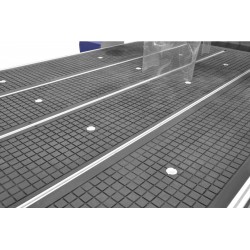

- Worktable made in hybrid technology

- Equipped with T-slots which make it possible to manually fix 2000×4000 mm material

- Table with 4 independent vacuum sections

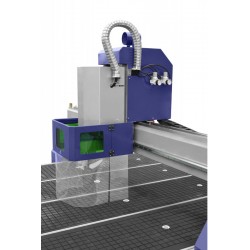

2. HQD spindle

- Brushless high grade spindle, featuring high 9 kW power

- Additionally equipped with an innovative air cooling system – not flood coolant

- Spindle design includes high-quality cartridge bearings, featuring quiet work and providing increased durability

- Spindle speed ranges from 4500 to 24000 rpm

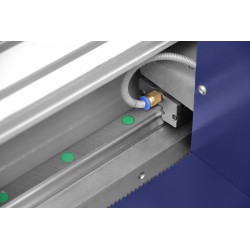

3. Vacuum pump

- Vacuum pump – 7.5 kW (max –440 mbar)

- 4 independent vacuum sections

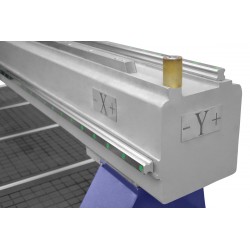

4. Drive

- SERVOmotors are used for driving machines of high power, providing appropriate speed in all directions

- X and Y axes include high quality toothed racks providing durability and accuracy

- Z-axis is driven through a high-quality ball screw

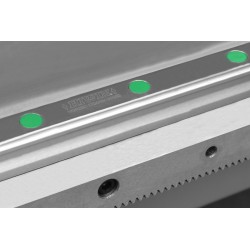

- All axes move along rail guides

- Machine equipped with a drive height sensor

- Frame drive on toothed racks, linear guides

- Linear bearings: trapezoid rails, Hiwin

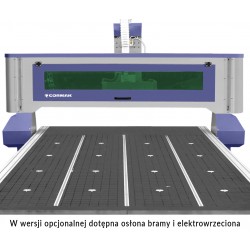

5. Design

- Moving frame made of cast iron of great rigidity, absorbing vibration

- Sturdy table design, made of high-quality materials. Heat-treated during manufacturing process

6. Tool holder

- Tool holder chuck ISO30 ER32 collet

- 8-position tool holder

- Tool height sensor

- ISO32 holders and 1/2", 4 mm, 8 mm, 10 mm tool fixture sleeves in the set

Software

- The machine is controlled by the industrial SYNTEC controller as in large machining centers. The controller includes: manipulator and LCD display.

- The software is included in the price of the machine (the software provides the ability to import files from Corel, Autocad, etc. Import / export of files, editor and text input and many other functions)

- The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

SERVO AC YASKAWA motors

Used to drive high-power machine tools, they provide adequate acceleration and speed in particular directions.

Milling machine with new software.

The machine is controlled by a JAPANESE industrial controller with a manipulator and LCD display

Technical data

| Working area |

2100x4100 mm |

| Z axis |

350 mm |

| Construction |

gate - cast iron / table - welded steel |

| Drives |

hybrid servo motors (AC YASKAWA) |

| Table type |

hybrid |

| Spindle power |

9 kW |

| Spindle |

HQD air cooling |

| Spindle rotation |

from 6000 to 24000 RPM |

| Power supply |

400 V, compressed air min. 8 bar |

| Re-positioning accuracy |

0,01 mm |

| Linear bearing |

trapezoidal rails, Hiwin carriages |

| Fastening the material |

vacuum, hybrid |

| Pump |

7.5 kW vacuum, 4 independent vacuum sections |

| Dimensions |

5070 x 2870 x 1900 mm |

| Weight |

3350 kg |