How do you choose the right carpentry machine for your workshop?

Understanding Your Workshop's Requirements

The first step in selecting the ideal industrial machines is assessing your workshop’s needs. The size of the workspace, the type of work performed, and the frequency of machine use are key factors in making the right decision. A large workshop can accommodate more robust machines, while smaller spaces may require compact or multifunctional solutions. Additionally, if your projects demand high precision and durability, investing in sturdy woodworking machines becomes essential.

If you're unsure where to start, explore the wide range of industrial machines available.

Comparing Different Types of Woodworking Machines

Not all woodworking machines are the same, and each has its specific application. Let’s discuss a comparison of woodworking machines.

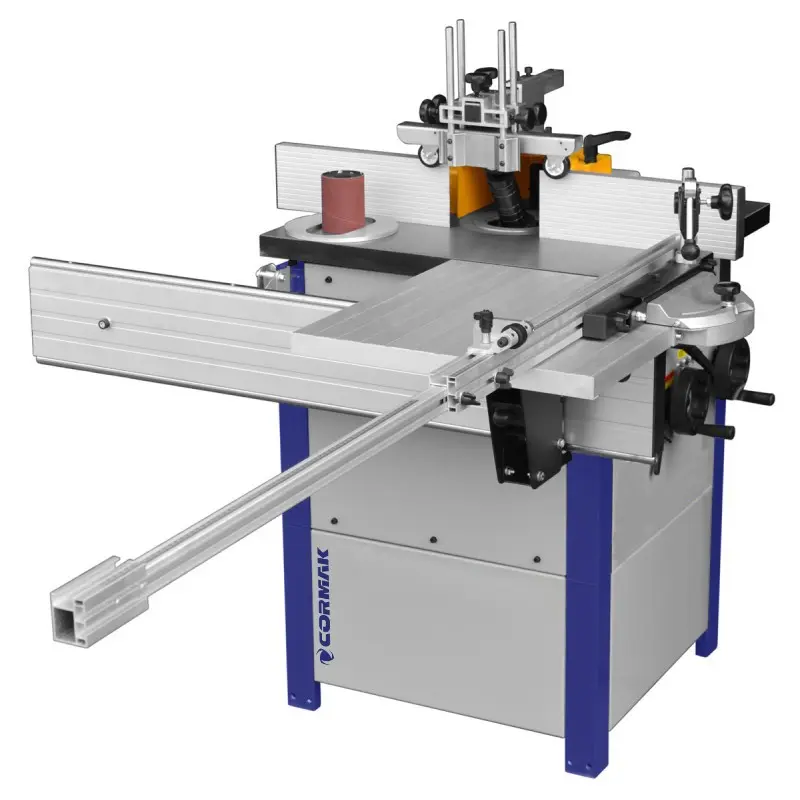

Wood milling machines are perfect for precision tasks, such as creating intricate patterns, shaping details, and profiling edges. They are an ideal choice for producing high-quality furniture or artistic woodworking projects. They offer high accuracy and control but are often specialized, meaning they may not be as versatile as other tools for more general tasks. If your focus is on decorative or custom elements, a milling machine will be an excellent choice.

Planers and jointers, on the other hand, are essential for surface preparation. A jointer smooths and straightens the edges of wood, while a planer ensures uniform thickness along the entire length of a board. These machines are crucial for woodworkers who need perfectly leveled elements for assembly or fitting. However, they are not designed for detailed or complex shaping, making them more suitable for structural work rather than finishing.

What Makes a Good Woodworking Machine?

Choosing the best woodworking machines requires focusing on quality and functionality. It is important to look for models made from durable materials that can withstand daily use in a heavily utilized workshop. Another key factor is precision—machines that offer clean and accurate cuts help save time and reduce material waste. Maintenance ease is also crucial—tools that are simple to clean and repair minimize downtime and ensure workflow continuity.

What should be the basic requirements for workshop machines? Safety features should not be overlooked. Modern woodworking machines are often equipped with emergency stop buttons, protective covers, and intuitive control systems, which reduce accident risks, making the workshop a safer and more efficient place to work.

Tips for Choosing the Right Machine

When selecting a woodworking machine, carefully considering the budget is essential. What are the tips for choosing machines for woodworkers? While it may be tempting to save on initial costs, investing in high-quality tools often proves more cost-effective in the long run due to their durability and reliability. Analyzing reviews and seeking recommendations from other woodworkers can provide valuable insights into a machine’s real-world performance. If possible, testing the equipment before purchase allows you to assess its power, ease of use, and suitability for your projects.

When selecting a woodworking machine, it is also worth considering the future growth of your workshop. As your business or skills expand, your machines should be able to adapt to increased demand or more complex projects. Choosing equipment with modern features, such as digital controls or modular accessories, can enhance versatility and ensure that they remain useful for years to come. Investing in high-quality woodworking machines now can save you from costly upgrades in the future, providing a solid foundation for expanding your capabilities and taking on more ambitious projects. Keep in mind all the criteria for woodworking machines.

Equip Your Workshop with Confidence

A good woodworking machine is more than just a tool—it’s an investment in your craft. By analyzing your workshop’s requirements, comparing different woodworking machines, and focusing on durability, precision, and safety, you can make an informed decision that supports your woodworking ambitions. Explore the wide range of models from the industrial machine manufacturer and find the perfect solution for your needs.