shopping_cart

€0.00

0 pcs.

0 pcs.

- Offer

- About us

- Financing

-

News

- Targi STOM w Kielcach 2024

- Targi ITM 2022 w Poznaniu

- Targi STOM w Kielcach 2022

- Targi Warsaw Industry Week 2021 w Warszawie

- Targi STOM w Kielcach 2021

- STOM 2020 Fair in Kielce

- Warsaw Industry Week 2019 Fair in Warsaw

- TOOLEX 2019 Fair in Sosnowiec

- ITM 2019 Fair in Poznań

- STOM 2019 Fair in Kielce

- Warsaw Industry Week 2018 Fair in Warsaw

- TOOLEX 2018 Fair in Sosnowiec

- STOOM-TOOL 2018 Fair in Kielce

- Warsaw Industry Week 2017 Fair in Warsaw

- TOOLEX 2017 Fair in Sosnowiec

- EMO 2017 Fair in HANOWER

- MACHTOOL 2017 Fair in Poznan

- STOM TOOL 2017 Fair in Kielce

- EUROTOOL 2016 Fair in Krakow

- TOOLEX 2016 Fair in Sosnowiec

- STOM-TOOL 2016 Fair in Kielce

- TOOLEX 2015 Fair in Sosnowiec

- MACHTOOL 2015 Fair in Poznań

-

Installations

-

Commissioning of CNC milling plotters

- Przedstawiamy Wam najnowszą produkcyjną przemysłową Frezarkę CNC do nestingu.

- Centrum obróbcze ploter frezujący CNC HK52 ze stołem podawczym i odbiorczym

- Ploter frezujący CNC C2040 ATC

- Uruchomienie C1212 Premium , C1520 Premium C2030 Premium

- Ploter frezujący C2030 Premium Cormak

- Centrum obróbcze frezarka CNC Cormak NST2131129A

- Ploter frezujący CNC M1325 do drewna i kamienia

- Centrum obróbcze ploter frezujący CNC HK52 ze stołem podawczym i odbiorczym

- Dostawa plotera frezującego CNC C1530

- Ploter frezujący CNC frezarka grawerka C1212

- Ploter frezujący CNC Cormak C1325

- Centrum obróbcze CNC C2030 IND

- Ploter frezarka CNC CORMAK C2030 ATC

- Ploter frezujacy C2131 Premium

- Plotery, frezarki CNC

- Dostawa plotera CNC C6090 Cormak

- Ploter frezujący CNC CORMAK C2030 w wersji ATC

- Ploter frezujący CNC CORMAK C1212 Premium

- Ploter frezujący Cormak CNC C6090

- Delivery of the C6090 machine

- Ploter frezujący CNC Cormak C1325 Premium

- Ploter frezujący CNC C1325

- Ploter frezujący Premium C1212

- Ploter frezującego C1530

- Ploter frezujacy C1212 Premium

- Ploter frezujący frezarka CNC Cormak C1525 Premium

- Ploter frezujący CNC Cormak C1325 Premium

- Ploter frezujący CNC Cormak C1212

- Frezarka CNC C6090 o polu roboczym 600x900.

- Ploter frezujący CNC C2141 ATC

- Dostawa i uruchomienie frezarki CNC C2141 w wersji ATC z automatyczną wymianą narzędzia o pełnym polu roboczym 2150x4100

- Dostawa i uruchomienie frezarki CNC C2131 w wersji ATC z automatyczną wymianą narzędzia o pełnym polu roboczym 2150x3100

- Przedstawiamy Państwu dostawę i instalację Plotera frezującego CNC o polu roboczym 1500x3000.

- Przedstawiamy dostawę maszyny CNC

- Ploter frezujący C1212

- CNC CORMAK C2040 PREMIUM Pompa Vacuum (pole robocze 2150 x 4200)

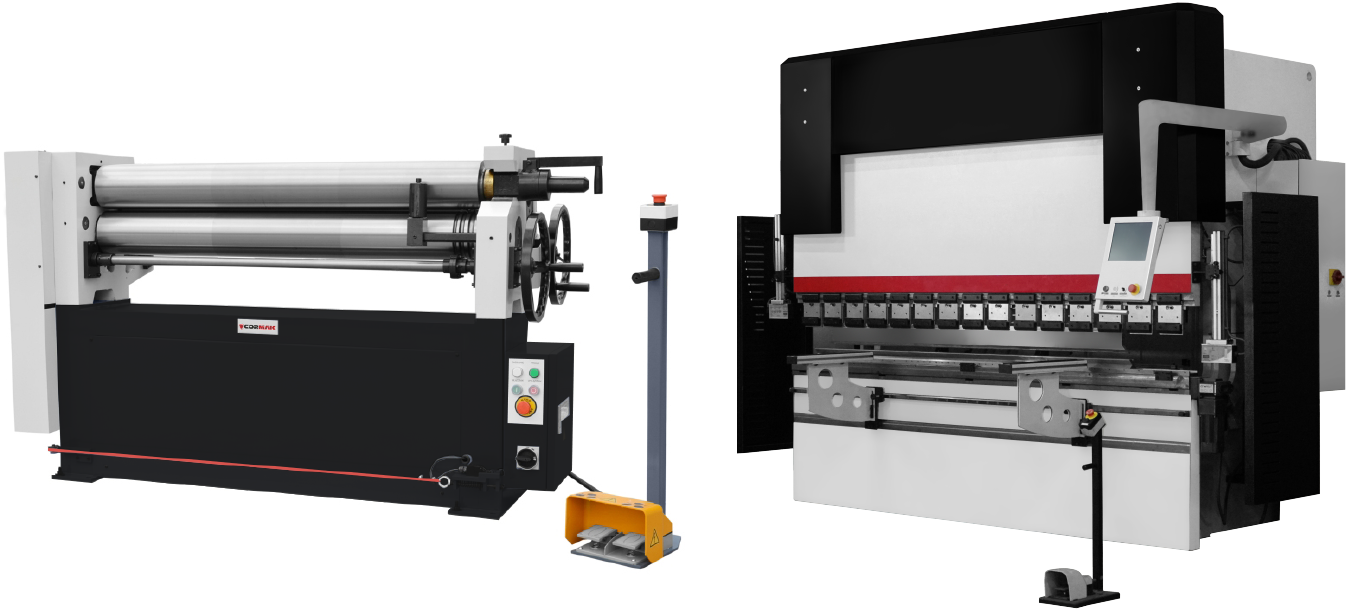

- Starting metal machines

-

Technologie laserowe i plazmy

- Wypalarka plazmowa PW-1530 WTK + źródło SPARTUS ProCUT 125CNC

- WIMED - LF3015CNR 1500W IPG

- Dzierzgoń Ut-Oil - LF3015GA 200W IPG

- LF3015GA 2000W IPG

- Magic Garden - LF3015E 1000W

- AND Garaże - LF6025G 2000W with exchanging platform

- Fiber laser cutting machine LF3015E 1000W

- LF3015GR 2000 W with a component for tubes and profiles

- Laser CO2 LC1830 150W

- Konstal- LF3015CNR

- Laser światłowodowy FIBER LF3015EP4 2000W

- Laser światłowodowy FIBER LF3015EP 3000W

- Laser światłowodowy FIBER LF3015GA 6000W

- Laser światłowodowy FIBER LF3015GEP 6000W

- Kościerzyna - LASER LF3015EP4 2000W

- Uruchomienie LASER LF3015GEP 4kW

- Charsznica - LASER LF3015GA 6000W

-

Commissioning of CNC milling plotters

- Service

-

Blog

- Przecinarka taśmowa: Klucz do efektywnej i precyzyjnej obróbki w przemyśle

- Wiertarka kolumnowa – niezbędne narzędzie w każdym zakładzie przemysłowym

- Przemysłowa Gratownica/Gratowarka do Metalu

- Przecinarki taśmowe automatyczne do metalu

- Giętarki Beztrzpieniowe do Rur i Profili: Rewolucja w Obróbce Metali

- Czym są maszyny CNC?

- Frezarki CNC – rodzaje i zastosowanie

- Obróbka skrawaniem CNC – na czym polega?

- Giętarki hydrauliczne do rur: rewolucja w przetwarzaniu metali

- Jak piaskować w piaskarce kabinowej: przewodnik dla początkujących i profesjonalistów.

- Opanuj sztukę frezowania: przewodnik użytkowania frezarki ręcznej

- Podstawy programowania MASZYN CNC z wykorzystaniem Sinumerik

- Odczyt cyfrowy DRO - Funkcje i zalety

- Czy wszystkie wózki podlegają pod UDT?

- Paleciak ręczny czy elektryczny?

- Spawanie laserowe - przyszłość czy kierunek spawalnictwa?

- Piaskowanie czy szkiełkowanie?

- Contact