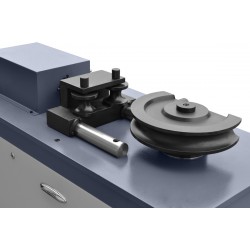

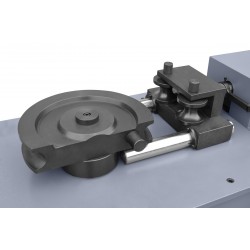

BENDMASTER80 Non-Mandrel Bending Machine for Tubes and Profiles

gross €9,114.61

Accurate and efficient industrial bending machine for steel, copper, aluminium and brass tubes. The possibility of selecting the optimum bending radius ensures achieving high-quality results without material deformation. Bending machines for tubes are used in low and high quantity manufacturing in the automotive and furniture industries. Main bending die is powered by a reduction gearbox and an electric motor. This bending machine is very simple to operate, with two operating modes: manual and semi-automatic. Straightforward and sturdy design provides reliable, long-term usage and ensures the simplicity of handling. By default comes with manual clamping. Hydraulic clamping is optional.

Write your review

* Required fields

I accept privacy policy rules or Cancel