The process of laser cutting

Laser cutting is a modern and widely used technique of machining materials. The cutting tool in this technique is a laser beam of high density energy, which cuts the material. Laser cutting is a great choice for machining metal, non-metal and composite materials. Thus, it is quite popular.

The course of the process of laser cutting

The process of laser cutting is based on the phenomenon of the laser beam working at its focal length, where the density and power of the beam particles are the highest, causing sudden melting, evaporation, ablation and heating of the material cut to the temperature of ignition. The place of the beam connecting with the material is cleaned with a quickly flowing gas, which removes the melted material while flowing in the axis of the moving beam. Laser cutting belongs to the hot machining techniques.

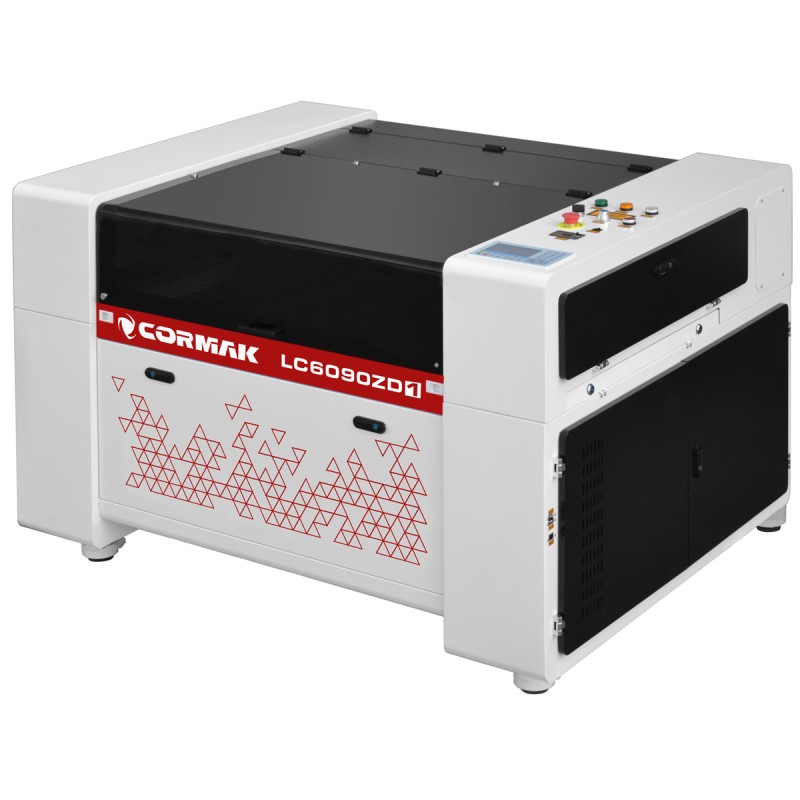

New model!

MACHINE EQUIPPED WITH AN IMPROVED CONTROLLER MODEL

- ability to control 4 axes independently,

- larger TFT display with a diagonal of 5 ",

- 13 languages (including Polish)

- numeric keys for easy entry, among others cutting parameters,

- external keys for direct control of the "Z" and "U" axes (they significantly speed up the work)

- external "FOCUS" key, setting the focus with one button (no need to search for the appropriate option in the menu)

- possible handling of files with higher capacity

- much higher efficiency than to the older models of controllers

- possibility of remote control as in the case of other CNC machines

| Dimensions |

1500 x 1500 x 1020 mm |

| Type of laser |

CO2 |

| Laser power |

90W (RECI W1 tube) (optional: 100W, 130W, 150W, 200W) |

| Weight of the device |

260 kg |

| Maximum cutting area |

600 x 900 mm |

| Positioning accuracy |

± 0.01 mm |

| Mechanical resolution |

0.0254 mm |

| Maximum power consumption |

1000W |

| Humidity during work |

5-95% |

| Temperature of work |

15–45 ℃ |

| Operating system |

Windows 95, 98, 2000, XP, Vista, 7, 8, 10 (32/64 bit) |

| Format of input files |

PLT, AI, DST, DXF, BMP |

| Compatible software |

CorelDraw AutoCAD Photoshop |

| Type of drive |

stepper motors |

| Communication |

USB |

| Head cooling |

water |

| Material cooling |

air, gas |

Write your review

* Required fields

I accept privacy policy rules or Cancel