- Reduced price

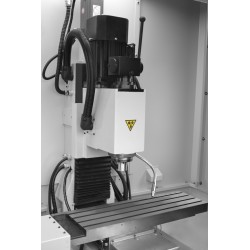

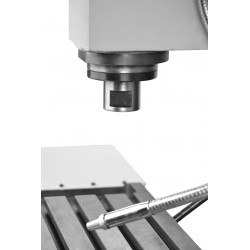

CNC milling machine Mill 350 CNC works in all 3 axes. It comes with such functions as: linear interpolation, circular interpolation, fixed cycles, tool alignment, subroutines and self-diagnosis. A range is 0-6000 RPM. With the usage of this device one can machine: flat and curved surfaces as well as threads and holes.

|

Table dimensions |

200×600 mm |

|

X-axis table feed |

350 mm |

|

Y-axis table feed |

240 mm |

|

Spindle vertical stroke |

310 mm |

|

T-slots width/length/number |

12/45/4 |

|

Maximum weight of workpiece |

50 kg |

|

Spindle taper |

R8 |

|

Distance between spindle and column |

268 mm |

|

Distance from spindle to table surface |

38–348 mm |

|

Main motor power |

1 kW |

|

X/Y/Z axes feed power |

6 Nm/6Nm/6Nm |

|

X/Y/Z axes quick travel |

4000 mm/min |

|

X/Y/Z axes feed speed |

0–3000 mm/min |

|

Positioning accuracy |

0.001 mm |

|

Spindle speed |

0–6000 rpm |

|

Dimensions |

1480×1300×1850 mm |

|

Weight |

580 kg |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

300 Ecoline CNC Milling Machine

CNC milling machine ideal for training purposes, equipped with SIEMENS Sinumerik808D control system. Although small when it comes to dimensions, it perfectly supplements assembly lines. This milling machine will help in offloading bigger machines.